LIPARAMETERI TSA SEHLAHISOA

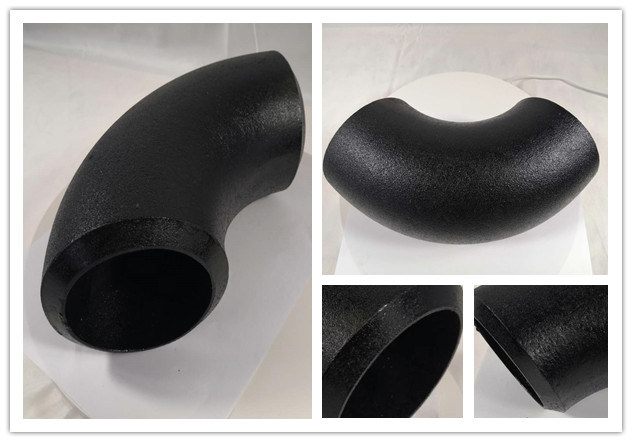

| Lebitso la Sehlahisoa | Setsoe sa phaephe |

| Boholo | Setsoe se se nang sekoli sa 1/2"-36" (setsoe sa SMLS), se kopantsoe ka setsoe sa 26"-110". Bophara bo boholo ka ho fetisisa ba kantle e ka ba 4000mm |

| E tloaelehileng | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, jj. |

| Botenya ba lebota | STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS le tse ding. |

| Tekanyo | 30° 45° 60° 90° 180°, jj. |

| Radius | LR/radius e telele/R=1.5D,SR/radius e kgutshwane/R=1D |

| QETA | Bevel end/BE/buttweld |

| Bokaholimo | 'mala oa tlhaho, o pentiloeng ka varnish, pente e ntšo, oli e thibelang mafome jj. |

| Thepa | Tšepe ea k'habone:A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH jj. |

| Tšepe ea liphaephe:ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 le tse ding. | |

| Tšepe ea motsoako oa Cr-Mo:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3, 12crmov, jj. | |

| Kopo | Indasteri ea peterole; indasteri ea lifofane le lifofane; indasteri ea meriana, mosi oa khase; setsi sa motlakase; mohaho oa likepe; kalafo ea metsi, jj. |

| Melemo | setoko se loketse, nako ea ho fana ka potlako; e fumaneha ka boholo bohle, e etselitsoe; boleng bo holimo |

LITLHOKOMELISO TSA PHAEPE

Lisebelisoa tsa liphaephe tse welletsoeng ka marago li kenyelletsa phala ea tšepe e otlolohileng, tee ea liphaephe tsa tšepe, sesebelisoa sa ho fokotsa liphaephe tsa tšepe, sekoahelo sa liphaephe tsa tšepe. Lisebelisoa tsohle tsa liphaephe tse welletsoeng ka marago, re ka li fana hammoho, re na le boiphihlelo ba tlhahiso ba lilemo tse 20 tse eketsehileng.

Haeba le uena u na le thahasello ea lisebelisoa tse ling, ka kopo tobetsa LINK e latetsoeng ho hlahloba lintlha.

TEE ea PHAEPE SEFOKOTSI SA LIPHAEPE SEKHURUMETSO SA PHAEPE PHAEPE E KOBEHILENG LITLHAKISO TSE THEHILOENG

Setsoe sa Pipe se Welded

Sekotjana sa phaephe ea tšepe ke likarolo tsa bohlokoa tsamaisong ea liphaephe bakeng sa ho fetola tsela eo mokelikeli o phallang ka eona. E sebelisoa ho hokahanya liphaephe tse peli tse nang le bophara bo tšoanang kapa bo fapaneng, le ho etsa hore phaephe e retelehele ntlheng e itseng ea likhato tse 45 kapa likhato tse 90.

Bakeng sa litsoe tsa phaephe ea indasteri, mofuta oa qetello ea khokahano ke weld ea butt, ho latela ANSI B16.25. Welded ea butt e ka hlalosoa e le weld ea butt, buttweld, bevel end.

Mofuta oa Setsoe

Setsoe se ka fapana ho tloha ho sekhutlo sa tataiso, mefuta ya kgokelo, bolelele le radius, le mefuta ya thepa.

E hlophisitsoe ka Tataiso ea Angle

Jwalo ka ha re tseba, ho ya ka tataiso ya mokelikeli wa diphaephe, setsoe se ka arolwa ka di-degree tse fapaneng, tse kang di-degree tse 45, di-degree tse 90, di-degree tse 180, e leng di-degree tse tlwaelehileng haholo. Hape ho na le di-degree tse 60 le di-degree tse 120, bakeng sa diphaephe tse ding tse ikgethang.

Bakeng sa setsoe sa likhato tse 90, setsoe sa 90d, kapa setsoe sa likhato tse 90 se boetse se hlalositsoe.

Sekhutlo sa litsoeng ke eng

Radius ea setsoe e bolela radius e kobehileng. Haeba radius e tšoana le bophara ba phaephe, e bitsoa radius e khutšoanyane, e boetse e bitsoa SR elbow, hangata bakeng sa liphaephe tsa khatello e tlase le tse lebelo le tlase.

Haeba radius e le kgolo ho feta bophara ba phaephe, R ≥ 1.5 Diameter, re e bitsa radius e telele e otlolohileng (LR Elbow), e sebediswang bakeng sa diphaephe tsa kgatello e phahameng le sekgahla se phahameng sa phallo.

Haeba radius e feta 1.5D, kamehla e bitsoa kobeho. Li-fittings tsa phaephe ea kobeho ea setsoe. Joalo ka setsoe sa 2d, kobeho ea 2d, setsoe sa 3d, kobeho ea 3d, jj.

Tlhophiso ka Boitsebiso

Tšepe ea k'habone, e boetse e bitsoa tšepe e bonolo kapa tšepe e ntšo. Tse kang ASTM A234 WPB

Ha o batla litsoele tsa tšepe e sa ruseng, ka kopo tobetsa sehokelo sena ho fumana lintlha tse ling:Litsoe tsa tšepe e sa hloekang

Mofuta oa Sebopeho

E ka ba setsoe se lekanang kapa Ho fokotsa setsoe

BOKAHO BA SETSOAKO

Ho phatloha ha lehlabathe

Kamora ho bopa mocheso, re hlophisa ho phatloha ha lehlabathe ho etsa hore bokaholimo bo hloeke 'me bo be boreledi.

Kamora ho phatloha ha lehlabathe, ho qoba ho ba le mafome, o lokela ho penta ka botsho kapa oil e thibelang mafome, Hot dip galvanized (HDG), epoxy, 3PE, bokaholimo bo nyametseng, jj. Seo se itshetlehile ka kopo ya moreki.

Kalafo ea mocheso

1. Boloka sampole ea thepa e tala hore e latele.

2. Lokisetsa kalafo ea mocheso ho latela maemo a tloaelehileng ka tieo.

HO TŠOAEA

Mesebetsi e fapaneng ea ho tšoaea, e ka kobeha, ea penta, ea label. Kapa ka kopo ea hau. Re amohela ho tšoaea LOGO ea hau.

LITŠOANTŠO TSE HLAKILENG

1. Bofelo ba bevel ho ya ka ANSI B16.25.

2. Ho penta lehlabathe pele, ebe ho penta hantle. Hape ho ka penta ka varnish.

3. Ntle le lamination le mapetso.

4. Ntle le ditokiso tsa ho tjheseletsa.

TLHAHLOBO

1. Litekanyo tsa litekanyo, tsohle li le ka har'a mamello e tloaelehileng.

2. Mamello ea botenya: +/- 12.5%, kapa ka kopo ea hau

3. PMI

4. Teko ea MT, UT, X-ray

5. Amohela tlhahlobo ea motho oa boraro

6. Phepelo ea MTC, setifikeiti sa EN10204 3.1/3.2

HO PHAKISA LE HO ROMELA

1. E pakiloe ka lebokose la plywood kapa pallet ea plywood ho latela ISPM15

2. re tla beha lethathamo la ho paka sephutheloana se seng le se seng

3. Re tla beha matšoao a ho romela thepa sephutheloana se seng le se seng. Mantsoe a matšoao a tla etsoa ka kopo ea hau.

4. Lisebelisoa tsohle tsa patsi ha li na mouoane

LBH

1. ANSI B16.9 ke eng?

ANSI B16.9 e bua ka maemo a American National Standards Institute (ANSI) bakeng sa di-fitting tsa diphaephe tse entsweng fekthering tse entsweng ka ho tjheseletsa di-butt-weld. E totobatsa boholo, mamello, thepa le ditlhoko tsa teko bakeng sa di-fitting tsa diphaephe tse entsweng ka ho tjheseletsa di-butt.

2. Lisebelisoa tsa liphaephe tse welletsoeng ka har'a marago ke eng?

Di-weld fittings tsa butt weld ke di-fittings tsa diphaephe tse kopantsweng ho ya fihla dipheletsong tsa diphaephe kapa di-fittings tse ding ho etsa lenonyello le matla, le sa dutleng. Kgokelo ya butt weld e etswa ka ho kenya pheletso ya phaephe kapa ho kenya ka hara sokete ya phaephe e nngwe kapa ho kenya lenonyello.

3. Setsoe sa ho tjheseletsa sa tšepe ea khabone sa likhato tse 180 ke eng?

Sekotwana se welletsoeng ka tšepe ea khabone sa likhato tse 180 ke sehokelo sa phaephe se sebelisetsoang ho fetola tsela ea phaephe likhato tse 180. Se fumaneha ka meralo e telele kapa e khutšoane ea radius 'me se entsoe ka thepa ea tšepe ea khabone. Sebelisa khokahano ea weld ea butt ho hokela setsoe ho phaephe kapa sehokelo se seng.

4. Litlhoko tsa litsoe tse welded ho ANSI B16.9 ke life?

ANSI B16.9 e totobatsa litekanyo, mamello, thepa le litlhoko tsa liteko bakeng sa litsoe tse welletsoeng. E fana ka tataiso mabapi le ts'ebetso ea tlhahiso, ho kenyeletsoa bophara ba kantle, botenya ba lebota, litekanyo tsa bohareng ho isa qetellong le radius ea kobeho bakeng sa litsoe tsa boholo bo fapaneng.

5. Melemo ea ho sebelisa tšepe ea carbon bakeng sa li-fitting tsa liphaephe tse welded ka har'a butt ke efe?

Tšepe ea khabone e sebelisoa haholo liphaepheng tse kopantsoeng ka har'a marako ka lebaka la matla a eona a matle, ho tšoarella le ho hanyetsa mafome. E ka mamella khatello e phahameng le maemo a mocheso o phahameng 'me e na le ts'ebetso e phahameng ea litšenyehelo. Liphaephe tsa tšepe ea khabone li loketse lits'ebetso tse fapaneng indastering ea oli le khase, petrochemical le tlhahiso ea motlakase.

6. Na tšepe ea khabone ea setsoe sa likhato tse 180 e ka sebelisoa lits'ebetsong tse nang le khatello e phahameng le tse nang le khatello e tlase?

E, litsoe tse welded ka tšepe ea khabone ea likhato tse 180 li ka sebelisoa lits'ebetsong tsa khatello e phahameng le e tlase. Leha ho le joalo, tekanyo e itseng ea khatello ea setsoe e lokela ho nahanoa ho latela litlhoko tsa ts'ebeliso. Lisebelisoa li tlameha ho netefatsoa bakeng sa ho lumellana le khatello e lebelletsoeng ea sistimi.

7. Na setsoe se welded sa tšepe ea carbon ea likhato tse 180 se loketse libaka tse senyang?

E, di-fitting tsa tshepe ya khabone ka kakaretso di loketse ho sebediswa dibakeng tse senyang. Leha ho le jwalo, mofuta le mahloriso a metswako e senyang di lokela ho nahanelwa ha ho kgethwa thepa. Dibakeng tse senyang haholo, ho ka hlokahala tshireletso e eketsehileng ya tshepe, jwalo ka dikobo tsa kantle kapa masela a kahare.

8. Na litsoe tsa tšepe ea khabone tsa likhato tse 180 li ka sebelisoa le liphaephe tse entsoeng ka thepa e 'ngoe?

E, litsoe tse welletsoeng ka tšepe ea khabone ka likhato tse 180 li ka sebelisoa le liphaephe tse entsoeng ka tšepe e sa ruseng, tšepe ea motsoako, litšepe tse se nang ferrous le lisebelisoa tse ling. Leha ho le joalo, bakeng sa ts'ebetso ea nako e telele, ho lumellana ha thepa le litlamorao tse ka bang teng tsa ho bola ha galvanic ho lokela ho nahanoa.

9. Ke liteko life tse entsoeng holim'a ANSI B16.9 carbon steel 180 degrees?

ANSI B16.9 e totobatsa liteko tse fapaneng ho netefatsa boleng le botšepehi ba litsoe tse welletsoeng ka tšepe ea khabone ea likhato tse 180. Liteko tsena li ka kenyelletsa tlhahlobo ea litekanyo, tlhahlobo ea pono, tlhahlobo ea ultrasound, tlhahlobo ea matla a ho tensile, tlhahlobo ea tšusumetso le liteko tse sa senyeheng (joalo ka ho kenella ha dae kapa tlhahlobo ea radiographic).

10. Na litsoe tsa tšepe ea khabone tsa likhato tse 180 li ka fetoloa kapa tsa tjheselletsoa sebakeng seo?

Litsoe tsa tšepe ea khabone tsa likhato tse 180 li ka fetoloa kapa tsa tjheselletsoa tšimong empa li lokela ho etsoa ke basebetsi ba tšoanelehang le ba nang le boiphihlelo ho latela maemo le mekhoa ea indasteri. Ho khothalletsoa ho buisana le moetsi kapa moenjiniere oa litsebi bakeng sa tataiso ho netefatsa polokeho le ts'ebetso ea lisebelisoa tse fetotsoeng.

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-PPR tris li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le li-elbow tsa tšepe ea alloy li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Liphaephe tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koentsha Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.

-

Tee ea 90 degree litsoeng e fokotsang tšepe ea carbon butt w ...

-

tšepe ea k'habone sch80 butt e welded pheletsong ea 12 inch sch4 ...

-

Asme b16.9 kemiso ea li-fittings tsa tšepe tsa 80 tee ...

-

tšepe ea k'habone e fokotsang sekhahla sa ASTM A105 Black ...

-

ANSI B16.9 Tšepe ea Khabone ea 45 Degree Welding Bend

-

Tšepe e sa ruseng e telele bend1d 1.5d 3d 5d radius 3 ...