LIPARAMETHE TSA SEHLAHISOA

| Lebitso la Sehlahisoa | Sefapano sa phaephe |

| Boholo | 1/2"-24" e se nang sekoli, e phuthetsoe ka 26"-110" |

| E tloaelehileng | ANSI B16.9, EN10253-2, DIN2615, GOST17376, JIS B2313, MSS SP 75, jj. |

| Botenya ba lebota | STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS le tse ding. |

| Mofuta | e lekanang/e otlolohileng, e sa lekanang/e fokotsang/e fokoditsweng |

| QETA | Bevel end/BE/buttweld |

| Bokaholimo | 'mala oa tlhaho, o pentiloeng ka varnish, pente e ntšo, oli e thibelang mafome jj. |

| Thepa | Tšepe ea k'habone:A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH jj. |

| Tšepe ea liphaephe:ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 le tse ding. | |

| Tšepe ea motsoako oa Cr-Mo:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3 jj. | |

| Kopo | Indasteri ea peterole; indasteri ea lifofane le lifofane; indasteri ea meriana, mosi oa khase; setsi sa motlakase; mohaho oa likepe; kalafo ea metsi, jj. |

| Melemo | setoko se loketse, nako ea ho fana ka potlako; e fumaneha ka boholo bohle, e etselitsoe; boleng bo holimo |

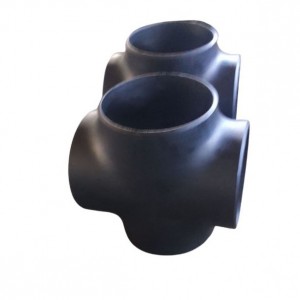

SELELEKELA SA SEFAPANO

Sefapano sa phaephe ke mofuta oa ho kenya phaephe o bōpehileng joaloka T o nang le liphaephe tse peli, ka 90° ho ea ho khokahano le mola o moholo. Ke karolo e khutšoanyane ea phaephe e nang le sehokelo se ka thoko. Phaephe e sebelisetsoa ho hokahanya liphaephe ka phaephe e ka lehlakoreng le letona le mola. Liphaephe li sebelisoa haholo e le liphaephe. Li entsoe ka thepa e fapaneng 'me li fumaneha ka boholo le liphetho tse fapaneng. Liphaephe li sebelisoa haholo marang-rang a liphaephe ho tsamaisa metsoako ea mokelikeli ea mekhahlelo e 'meli.

MOFUTA OA SEFAPANO

- Ho na le li-t-shirt tse otlolohileng tsa liphaephe tse nang le masoba a boholo bo lekanang.

- Li-tee tsa liphaephe tse fokotsang li na le lesoba le le leng la boholo bo fapaneng le masoba a mabeli a boholo bo tšoanang.

-

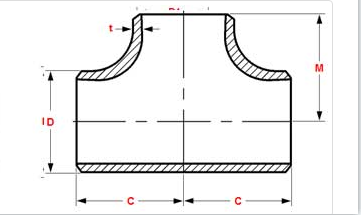

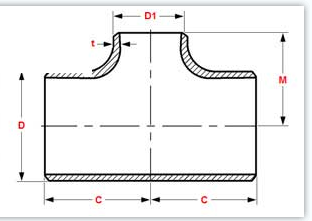

MAMETLELELO A MATŠOAO A ASME B16.9 A Otlolohileng

Boholo ba Pipe bo Ikhethileng 1/2 ho isa ho 2.1/2 3 ho isa ho 3.1/2 4 5 ho isa ho 8 10 ho isa ho 18 20 ho isa ho 24 26 ho isa ho 30 32 ho isa ho 48 Kantle ho Dia

ho Bevel (D)+1.6

-0.81.6 1.6 +2.4

-1.6+4

-3.2+6.4

-4.8+6.4

-4.8+6.4

-4.8Ka Hare ho Dia Qetellong 0.8 1.6 1.6 1.6 3.2 4.8 +6.4

-4.8+6.4

-4.8Setsi sa ho Fela (C / M) 2 2 2 2 2 2 3 5 Lebota Thk (t) Bonyane 87.5% ea Boima ba Lebota bo Ikhethileng Mamello ea litekanyo e ka limilimithara ntle le haeba ho bontšitsoe ka tsela e 'ngoe' me e lekana ± ntle le joalokaha ho boletsoe.

TLHAHLOBO

1. Litekanyo tsa litekanyo, tsohle li le ka har'a mamello e tloaelehileng.

2. Mamello ea botenya: +/- 12.5%, kapa ka kopo ea hau

3. PMI

4. Teko ea MT, UT, PT, X-ray

5. Amohela tlhahlobo ea motho oa boraro

6. Phepelo ea MTC, setifikeiti sa EN10204 3.1/3.2

HO PHAKISA LE HO ROMELA

1. E pakiloe ka lebokose la plywood kapa pallet ea plywood ho latela ISPM15

2. re tla beha lethathamo la ho paka sephutheloana se seng le se seng

3. Re tla beha matšoao a ho romela thepa sephutheloana se seng le se seng. Mantsoe a matšoao a tla etsoa ka kopo ea hau.

4. Lisebelisoa tsohle tsa patsi ha li na mouoane

LBH

1. ASME B16.9 ke eng?

ASME B16.9 ke tekanyetso e ntshetsweng pele ke Mokhatlo wa Amerika wa Baenjiniere ba Mekaniki (ASME) e akaretsang di-weld fittings tse entsweng fekthering tse entsweng ka ho qhibilihiswa. E fana ka boholo, mamello le ditlhaloso tsa thepa bakeng sa mefuta e fapaneng ya di-weld fittings tsa butt.

2. A105 ke eng?

A105 ke tlhaloso ea litšepe tsa tšepe ea khabone tse sebelisoang likarolong tsa sejana sa khatello. E akaretsa likarolo tsa liphaephe tsa tšepe ea khabone tse entsoeng ka mokhoa o ...

3. A234WPB ke eng?

A234WPB ke tlhaloso ea li-fitting tsa tšepe ea khabone le alloy tse sebelisoang mochesong o mahareng le o phahameng. Li-fitting tsena li etsoa ka mekhoa ea kaho e se nang sekoli kapa e phuthetsoeng 'me hangata li sebelisoa lits'ebetsong tsa liphaephe.

4. Sefapano se nang le bophara bo lekanang le ba butt corrugated ke eng?

Sefapano sa ho weld ka bophara bo lekanang le ba butt weld ke sehokelo sa phaephe se sebediswang ho fana ka dikgokelo tsa makala ditsamaisong tsa diphaephe. Se na le masoba a mane a boholo bo lekanang, monyako o le mong le mekero e meraro e hlophisitsweng ka sebopeho sa sefapano. Se dumella maro ho phalla ka mahlakoreng a fapaneng mme hangata se sebediswa diphaepheng tse kopanang.

5. Thepa ea sebopeho ea ASME B16.9 A105 A234WPB carbon steel butt e welded equivalent dayameter cross ke efe?

ASME B16.9 A105 A234WPB Sefapano sa ho wellisa serethe sa tšepe ea khabone se lekanang le bophara se entsoe ka thepa ea tšepe ea khabone, haholo-holo lintho tse betliloeng ke A105 'me lipeipi ke A234WPB. Lisebelisoa tsena li tsebahala ka matla a tsona, ho tšoarella le ho hanyetsa mafome.

6. Ke boholo bofe bo fumanehang bakeng sa difapano tsa ASME B16.9 A105 A234WPB tsa tshepe ya khabone tse kopanyang bophara bo lekanang?

ASME B16.9 A105 A234WPB Carbon Steel Butt Weld Equal Diameter Crosses di fumaneha ka boholo bo fapaneng ho tloha ho bo bonyenyane ho isa ho bo boholo. Ditekanyo tse ikgethang di itshetlehile ka ditlhoko tsa sistimi ya diphaephe mme di ka etswa ka tsela e ikgethang.

7. Tekanyo ea khatello ea ASME B16.9 A105 A234WPB carbon steel butt cross e lekanang le bophara ke efe?

ASME B16.9 A105 A234WPB Litekanyetso tsa khatello bakeng sa weld ea tšepe ea carbon butt cross e lekanang le bophara lia fapana ho latela boholo, thepa le maemo a mocheso. Litekanyetso tsena tsa khatello li boletsoe tekanyetsong ea ASME B16.9 'me li lokela ho lateloa ho netefatsa ts'ebetso e sireletsehileng le e tšepahalang.

8. Na ASME B16.9 A105 A234WPB carbon steel butt weld e lekanang bophara sefapano e ka sebediswa ditshebedisong tsa mocheso o phahameng le o tlase?

E, difapano tsa ASME B16.9 A105 A234WPB tsa tshepe ya khabone tse lekanang le bophara di a fumaneha bakeng sa ditshebediso tsa mocheso o phahameng le o tlase. Leha ho le jwalo, ho bohlokwa ho kgetha thepa e nepahetseng le ho netefatsa hore ditlhoko tsa mocheso le kgatello ya moralo di a fihlellwa.

9. Na ASME B16.9 A105 A234WPB tšepe ea carbon butt e kopantsoe ka bophara bo lekanang e loketse libaka tse senyang?

ASME B16.9 A105 A234WPB sehokelo sa tšepe ea carbon se kopantsoeng ka bophara bo lekanang se ka sebelisoa libakeng tse senyang hanyane. Leha ho le joalo, bakeng sa libaka tse senyang haholo, ho khothalletsoa ho sebelisa thepa e sa senyeheng ke mafome kapa ho sebelisa liphahlo tse ling tse sireletsang ho eketsa bophelo ba litšebeletso tsa lisebelisoa.

10. Na ASME B16.9 A105 A234WPB carbon steel butt welded symbols e lekanang bophara e sebelisoa haholo?

E, ASME B16.9 A105 A234WPB Carbon Steel Butt Weld Contour Cross e fumaneha haholo ka bahlahisi ba lumelletsoeng, bafepedi le barekisi. Ho bohlokoa ho li reka mehloling e tsebahalang ho netefatsa hore maemo le litlhaloso tsa boleng lia fihlelleha.

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-tri tsa PPR li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le litsoe tsa tšepe e kopantsoeng li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Li-fitting tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koetlisetsa Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.

-

Tšepe e sa ruseng e telele bend1d 1.5d 3d 5d radius 3 ...

-

A234WPB e ntšo e se nang sekoli ea tšepe e loketseng phala e nang le ...

-

Setsoe se loketseng phaephe sa 3050mm API 5L X70 WPHY70

-

DN50 50A sch10 90 litsoeng phala e loketseng li-seamles tsa LR ...

-

Serope se kopantsoeng sa tšepe e sa hloekang se nang le seamless 321ss ...

-

tšepe ea k'habone e kobehileng likhato tse 45 3d bw 12.7mm WT AP ...