Bolt ea mofuta o fapaneng

Phapang pakeng tsa dibolthi le dikurufu e ka mahlakoreng a mabedi: e nngwe ke sebopeho, karolo ya stud ya bolthi e hlokahala ka thata hore e be cylindrical, e sebedisetswang ho kenya nate, empa karolo ya stud ya sekrufu ka dinako tse ding e na le sebopeho se kobehileng kapa esita le ntlha; e nngwe ke Ha o sebedisa mosebetsi, sekrufu se kenngwa ka hara thepa e shebilweng ho ena le nate. Maemong a mangata, dibolthi le tsona di sebetsa ka bonngwe, mme di kenngwa ka ho toba ka hara lesoba le tjhekilweng pele, ntle le tlhoko ya nate ho sebelisana le yona. Nakong ena, bolthi e arolwa e le skrufu ho ya ka mosebetsi.

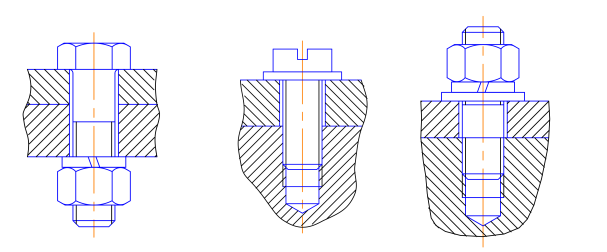

Sebopeho le morero oa hlooho ea bolutu li arotsoe ka liboutu tsa hlooho tse nang le mahlakore a tšeletseng, liboutu tsa hlooho tse sekoere, liboutu tsa hlooho tse chitja tse halofo, liboutu tsa hlooho tse koahetsoeng ka lehlakoreng le leng, liboutu tse nang le masoba, liboutu tsa hlooho tse nang le li-T, liboutu tsa hlooho ea hook (motheo) le tse ling.

Khoele ea kholomo e ka aroloa ka khoele e mahoashe, khoele e tšesaane le khoele ea lisenthimithara, kahoo e bitsoa bolt e tšesaane le bolt ea lisenthimithara.

Tshebetso ea Tlhahiso

Sa pele, ho otla ha pele ho tsamaya ho lokisa terata bakeng sa ho bopa, ebe ho otla ha bobedi ho tsamaya ho etsa terata hape le ho bopa sehlahiswa se fedileng. Mokgweng wa ho tshwara dihlooho ka tsela e batang, ho otla ha die e tsitsitseng (ho hatella) le ho hata (ho batalla) ho a shwa (ho phunya)

Palo ea lihlooho (lihlooho) ha e tšoane. Li-screw tse ling tse rarahaneng li ka hloka li-punch tse ngata ho theha hammoho, e leng se hlokang lisebelisoa tsa liteishene tse ngata ho etsa hore sekurufu se thehoe. Kamora ho sisinyeha ha sekurufu, hlooho ea sekurufu e phethiloe, empa karolo ea shaft ea sekurufu ha e so ferekoe. Mokhoa oa ho etsa khoele ea sekurufu ke ho ferekoa ha khoele. Ho ferekoa ha khoele ke tšebeliso ea li-dies tse peli tse potolohang tsa khoele (lipoleiti tsa ho hohla) tse nang le meno a khoele ho hatella sekheo sa cylindrical se entsoeng ke mochini oa amulti-station kapa oa hlooho bohareng.

Kamora ho hloa le ho hohla meno, screw eohle e hlahisitsoe. Ehlile, e le ho etsa hore ponahalo ea screw e be e khanyang le e betere, ts'ebetso ea kalafo ea bokaholimo hangata e etsoa. Joalo ka ho hloekisa le ho kenya li-screw tsa tšepe e sa hloekang, ho kenya ka motlakase holim'a li-screw tsa tšepe ea khabone, jj. E entsoe ka mebala e fapaneng ea li-fasteners tsa screw.

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-PPR tris li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le li-elbow tsa tšepe ea alloy li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Liphaephe tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koentsha Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.