Liparamente tsa sehlahisoa

| Lebitso la sehlahisoa | liphaephe tse se nang moedi, phaephe ea ERW, liphaephe tsa DSAW. |

| E tloaelehileng | ASME B36.10M, API 5L, ASTM A312, ASTM A213. ASTM A269, joalo-joalo |

| Thepa | Tšepe ea k'habone: A106 GR B, A53 GR B,ASTM A333 GR 6 jj. |

| Motsoako oa Cr-Mo: A335 P11, A335 P22, A335 P12, A335 P5, A335 P9, A335 P91, joalo-joalo | |

| Tšepe ea phaephe: API 5L GR B, API 5L X42, API 5L X46, API 5L X56, API 5L X60, API 5L X65, API 5L X70, jj. | |

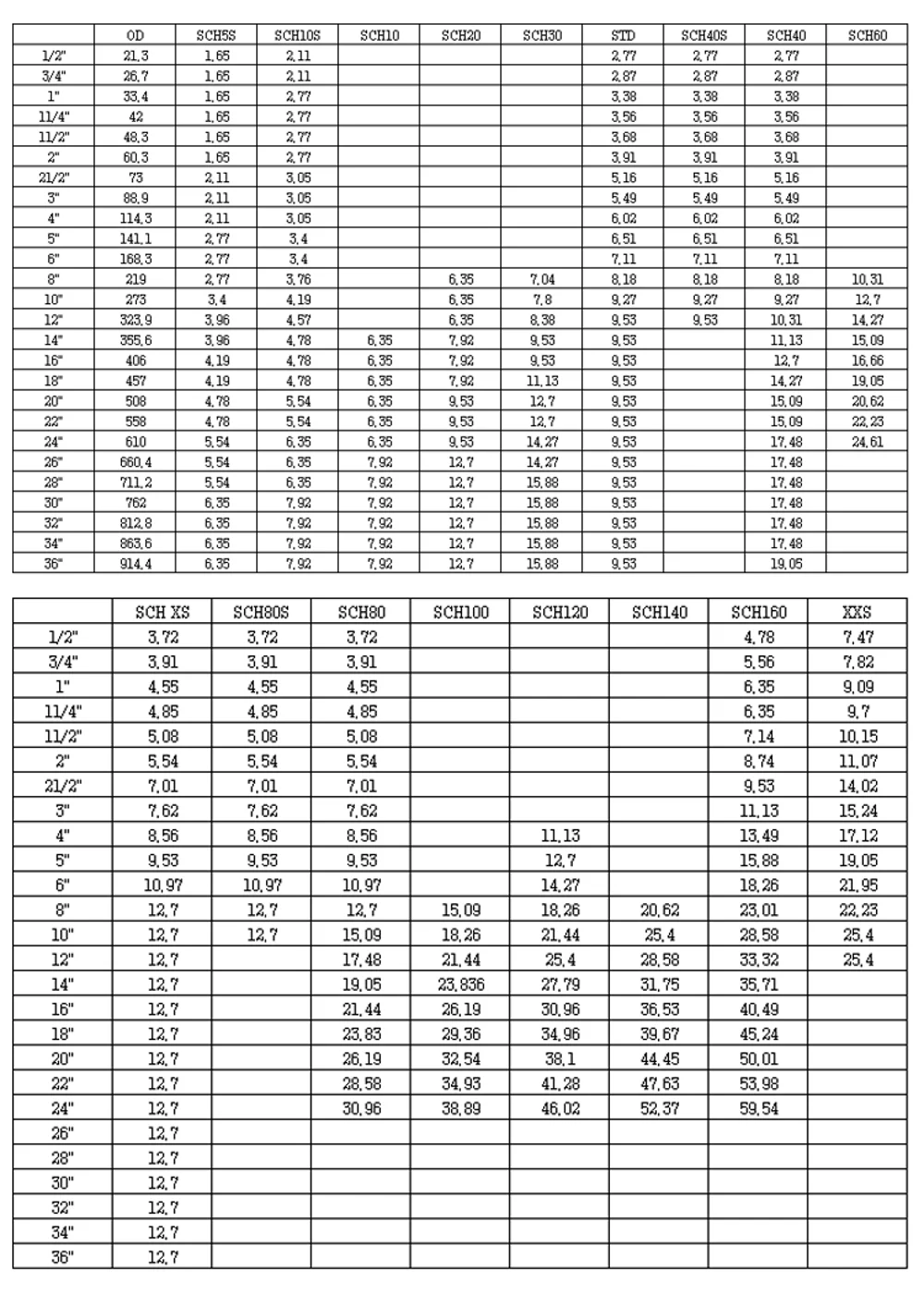

| OD | 3/8" -100", e etselitsoeng uena |

| Botenya ba lebota | SCH5S SCH10S, SCH10, SCH20, SCH30, SCH40S, STD, SCH40, SCH80S, SCH80, XS, SCH60, SCH100, SCH120, SCH140, SCH160,XXS, e etselitsoeng uena, jj. |

| Bolelele | 5.8m, 6m, 11.8m, 12m, kapa kamoo ho hlokahalang |

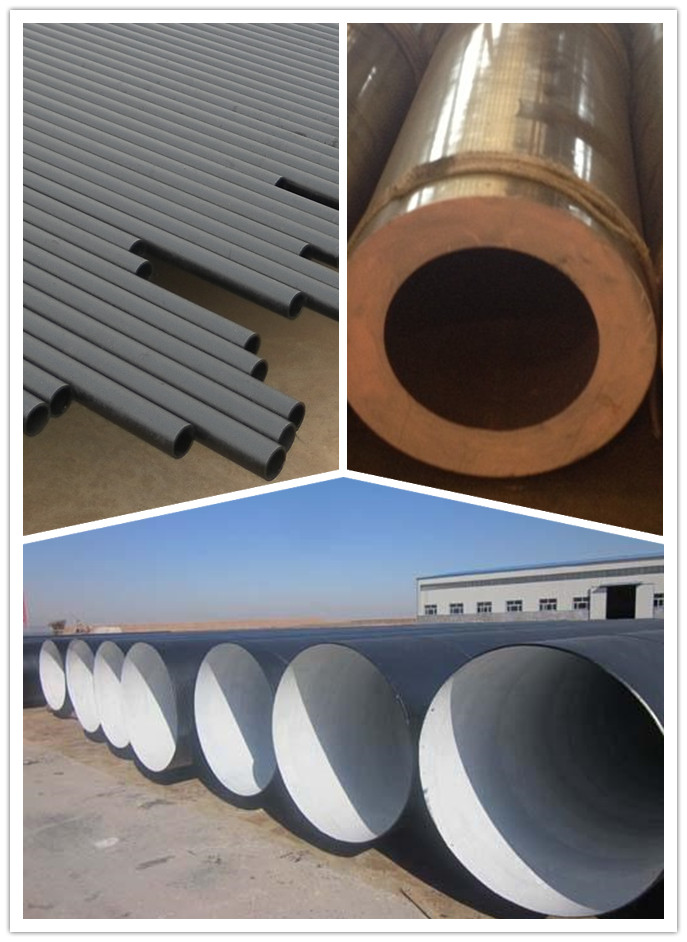

| Bokaholimo | Pente e ntšo, pente ea 3PE, pente e 'ngoe e khethehileng, jj. |

| Kopo | Phaephe ea tšepe e sa hloekang e sebelisoang haholo peteroleng, indastering ea lik'hemik'hale, motlakase, boiler, e hanelang mocheso o phahameng, e hanelang mocheso o tlase, e hanelang mafome., tšebeletso e bolila, jj. |

| Boholo ba liphaephe bo ka etsoa ho latela litlhoko tsa bareki. | |

| Mabitso | Haeba o na le lipotso, ka kopo ikutloe u lokolohile ho ikopanya le 'na. Re na le bonnete ba hore potso ea hau kapa litlhoko tsa hau li tla fumana tlhokomelo kapele. |

Linepe tse qaqileng

1. Pente e nang le varnish, e ntšo, pente ea 3 LPE jj.

2. Qetello e ka ba pheletso e bevel kapa pheletso e tloaelehileng

3. bolelele bo ka etsoa ha ho kopuoa, bo hlophisitsoe.

Tlhahlobo

1. Teko ea PMI, UT, RT, X-ray.

2. Teko ea tekanyo.

3. Phepelo ea MTC, setifikeiti sa tlhahlobo, EN10204 3.1/3.2.

4. Setifikeiti sa NACE, tšebeletso e bolila

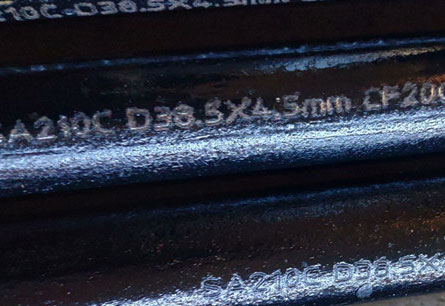

Ho tšoaea

Letshwao le hatisitsoeng kapa le kobehileng ha ho kopuoa. OEM e a amoheleha.

Ho paka le ho Romela

1. Qetello e tla sireletsoa ka likheo tsa polasetiki.

2. Liphaephe tse nyane li pakiloe ka lebokose la plywood.

3. Liphaephe tse kholoanyane li pakoa ka ho li kopanya.

4. Sephutheloana sohle, re tla beha lethathamo la ho paka.

5. Matšoao a ho romela ha re kopa

Tlhaloso ea Sehlahisoa

Liphaephe tsa tšepe ea khabone li arotsoe ka liphaephe tsa tšepe tse phutholohileng tse chesang le tse batang tse phutholohileng (tse huloang).

Phaephe ea tšepe ea khabone e phutholohileng e arotsoe ka phala ea tšepe e akaretsang, phala ea tšepe ea boiler e nang le khatello e tlase le e mahareng, phala ea tšepe ea boiler e nang le khatello e phahameng, phala ea tšepe ea alloy, phala ea tšepe e sa hloekang, phala ea peterole e petsohang, phala ea tšepe ea jeoloji le liphaephe tse ling tsa tšepe.

Phaephe ea tšepe ea khabone e phutholohileng e batang (e daelang) ho phaella ho phaephe ea tšepe e akaretsang, phaephe ea tšepe ea boiler e nang le khatello e tlase le e mahareng, phaephe ea tšepe ea boiler e nang le khatello e phahameng, phaephe ea tšepe ea alloy, phaephe ea tšepe e sa hloekang, phaephe ea ho petsoha ha oli, phaephe e 'ngoe ea tšepe, e boetse e kenyelletsa phaephe ea tšepe e nang le lebota le lesesaane la carbon, phaephe ea tšepe e nang le lebota le lesesaane la alloy, phaephe ea tšepe e nang le sebopeho se khethehileng. Bophara ba ka ntle ba phaephe e se nang sekoli e phutholohileng e chesang ka kakaretso bo boholo ho feta 32mm, botenya ba lebota ke 2.5-75mm, bophara ba ka ntle ba phaephe ea tšepe e se nang sekoli e phutholohileng e batang e ka ba 6mm, botenya ba lebota e ka ba 0.25mm, bophara ba ka ntle ba phaephe e nang le lebota le lesesaane e ka ba 5mm, botenya ba lebota bo ka tlase ho 0.25mm, 'me boholo bo nepahetse ho feta ba phaephe e se nang sekoli e phutholohileng e chesang.

Phaephe e akaretsang ea tšepe ea khabone: e entsoe ka tšepe ea 10, 20, 30, 35, 45 le tšepe e 'ngoe ea boleng bo holimo ea carbon junction 16Mn, 5MnV le tšepe e 'ngoe ea sebopeho se tlaase kapa 40Cr, 30CrMnSi, 45Mn2, 40MnB le tšepe e 'ngoe ea alloy e phutholohileng e chesang kapa e batang. Liphaephe tse se nang seam tse entsoeng ka tšepe ea khabone e tlase tse kang 10 le 20 li sebelisoa haholo bakeng sa liphaephe tsa lipalangoang tsa metsi. 45, 40Cr le phaephe e 'ngoe ea tšepe ea khabone e mahareng e se nang seam ho etsa likarolo tsa mechini, tse kang likoloi, likarolo tsa terekere. Phaephe ea tšepe ea khabone e sebelisoang ka kakaretso ho netefatsa matla le teko ea ho batalla. Liphaephe tsa tšepe tse phutholohileng tse chesang li tlisoa boemong ba ho phutholohang kapa ba phekoloang ka mocheso; Li tlisoa boemong ba ho phutholohang ka mocheso.

LBH

1. ASTM A312 ke eng?

ASTM A312 ke tlhaloso bakeng sa phaephe ea tšepe e sa hloekang ea austenitic e se nang sekoli, e phuthetsoeng, le e batang haholo e sebelisoang mochesong o phahameng le tikolohong e senyang ka kakaretso.

2. Phaephe ea tšepe e ntšo ke eng?

Phaephe e ntšo ea tšepe ke phaephe ea tšepe e sa kenngoeng ka galvanized e nang le lesira la oxide ea tšepe e lefifi. Lesela lena le eketsa ho hanyetsa mafome 'me le fa phaephe ponahalo ea eona e ntšo e ikhethang.

3. Melemo ea ho sebelisa liphaephe tse phutholohileng ka mocheso ke efe?

Liphaephe tse phutholohileng ka mocheso li fana ka melemo e 'maloa, ho kenyeletsoa le ho ntlafala ha sebopeho, qetello e phahameng ea bokaholimo, ho nepahala ho ntlafalitsoeng ha boholo le thepa e ntlafalitsoeng ea mechini. Hangata li sebelisoa lits'ebetsong tse hlokang liphaephe tse matla, tse tšoarellang, le tse entsoeng ka nepo.

4. Ke hobane'ng ha liphaephe tsa tšepe ea carbon li ratoa haholo liindastering tse fapaneng?

Liphaephe tsa tšepe ea khabone li tumme liindastering tse fapaneng ka lebaka la matla a tsona, theko e tlase le ho tenyetseha ha tsona. Li sebelisoa haholo lipatlisisong tsa oli le khase, ts'ebetsong ea lik'hemik'hale, tlhahiso ea motlakase, likoloi, kaho le masimong a mang a mangata.

5. Ts'ebetso ea tlhahiso ea phaephe ea tšepe e ntšo e fapane joang le liphaephe tse ling?

Ho etsoa ha liphaephe tsa tšepe e ntšo ho kenyelletsa mekhoa e itseng ea ho futhumatsa le ho pholisa. Tšepe e futhumatsoa mochesong o phahameng, e phuthoa ka har'a liphaephe, ebe e pholisoa ka potlako ho etsa lera le tsitsitseng la oxide ea tšepe e fang phaephe 'mala oa eona o motšo.

6. Litšebeliso tsa phala ea tšepe e ntšo ea ASTM A312 ke life?

Phaephe ea tšepe e ntšo ea ASTM A312 e sebelisoa liindastering tse fapaneng, ho kenyeletsoa oli le khase, lik'hemik'hale tsa peterole, kalafo ea metsi, liphaephe, litsamaiso tsa HVAC, litšehetso tsa meaho le tlhahiso e akaretsang. Hangata e sebelisoa ho tsamaisa maro le likhase tlas'a khatello e phahameng le maemo a mocheso o phahameng.

7. Na liphaephe tsa tšepe e ntšo li ka sebelisoa kantle?

E, phaephe ea tšepe e ntšo e fumaneha bakeng sa lits'ebetso tsa kantle. Seaparo sa tšepe ea oxide se fana ka tšireletso e ntle khahlanong le mafome, e leng se etsang hore e lokele maemo a fapaneng a tikoloho. Leha ho le joalo, liaparo tse ling tse sireletsang li ka hlokahala libakeng tse senyang haholo.

8. Na lipeipi tse phutholohileng tse chesang li loketse lits'ebetso tsa boenjiniere bo nepahetseng?

E, liphaephe tse phutholohileng tse chesang li sebelisoa haholo lits'ebetsong tsa boenjiniere ba ho nepahala. Ho nepahala ha eona ho ntlafalitsoeng ka boholo le qetello e phahameng ea bokaholimo ho etsa hore e be ntle bakeng sa ho etsa likarolo tse nepahetseng haholo, mechini le meaho e hlokang mamello e tiileng.

9. Melemo ea liphaephe tsa tšepe ea khabone ke efe ha e bapisoa le thepa e 'ngoe?

Liphaephe tsa tšepe ea khabone li fana ka melemo e 'maloa, ho kenyeletsoa matla a ho thaepa a phahameng, ho hanyetsa ho tsofala ho hoholo, ho sebetsa hantle ha mechini le bonolo ba ho tjheseletsa. Hape e theko e tlase ebile e fumaneha ka boholo le litlhaloso tse fapaneng.

10. Na phaephe ea tšepe e ntšo ea ASTM A312 e loketse lits'ebetso tsa mocheso o phahameng?

E, phaephe e ntšo ea tšepe ea ASTM A312 e etselitsoe ka ho khetheha lits'ebetso tsa mocheso o phahameng. Li na le khanyetso e ntle ea mocheso 'me li loketse ho tsamaisa mouoane, metsi a chesang le maro a mang a mocheso o phahameng.

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-PPR tris li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le li-elbow tsa tšepe ea alloy li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Liphaephe tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koentsha Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.

-

Inconel 718 601 625 Monel K500 32750 Incoloy 82...

-

Theko ea fektheri ea China incoloy 840 Inconel 601 625 ...

-

Hot Ina Galvanized 6 Inch Sch 40 A179 Gr.B Round ...

-

Phaephe e se nang sekoli ea Incoloy Alloy 800 ASTM B407 ASME ...

-

Tšepe e sa Khaotseng ea 316L Tube e Nyenyane ea Sepolishe ...

-

JIS Inconel600 Inconel800h Inconel 625 e se nang seamless...