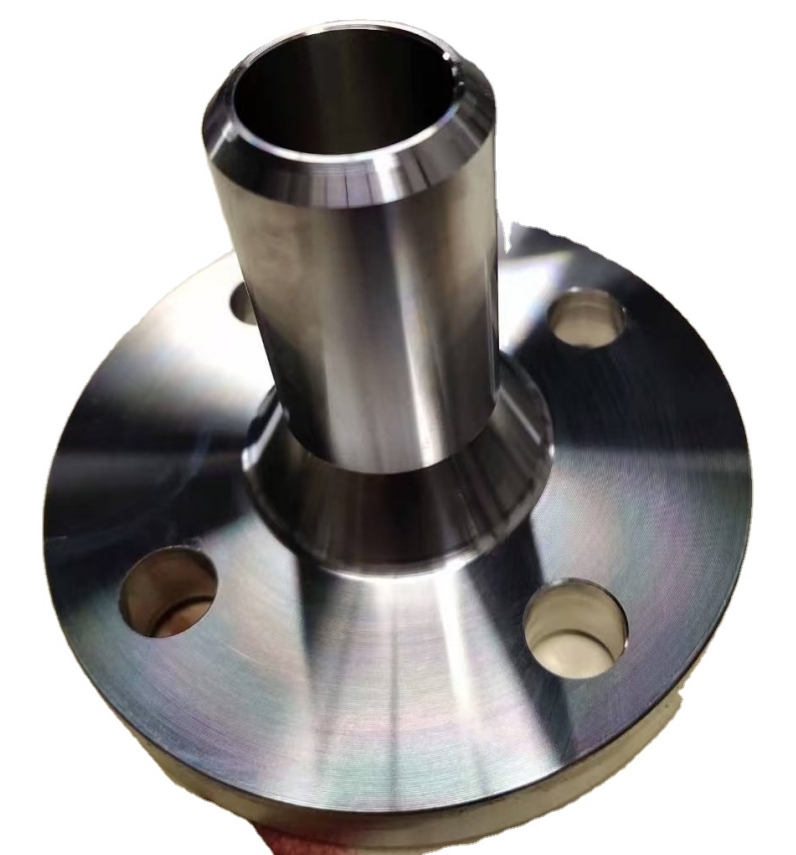

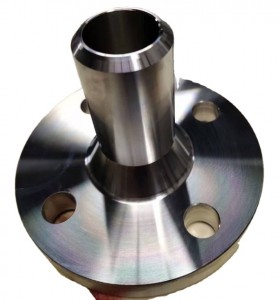

Flange e Ikhethileng ea ho Weld Neck (LWN)

Li-flange tsa rona tse entsoeng ka mokhoa o ikhethileng oa Long Weld Neck (LWN) li emela tharollo ea ho qetela bakeng sa lits'ebetso tsa bohlokoa tsa liphaephe moo li-flange tse tloaelehileng li ke keng tsa fihlela litlhoko tse ikhethang tsa projeke. Li entsoe bakeng sa maemo a feteletseng a ts'ebeletso libakeng tse ling tsa leoatle, tsa petrochemical, tsa tlhahiso ea motlakase le tsa ts'ebetso ea khatello e phahameng, li-flange tsena li etselitsoe litlhoko tse itseng tsa ts'ebetso ka boenjiniere bo tsoetseng pele le tlhahiso e nepahetseng.

Ho fapana le dikarolo tse seng tsa shelefong, flange e 'ngoe le e 'ngoe ea LWN e etselitsoeng motho ka mong e feta tlhahlobong e tebileng ea moralo ho netefatsa ts'ebetso e ntle tlas'a maemo a itseng a khatello, mocheso, mafome le khatello ea mechini. Moralo o atolositsoeng oa molala o fana ka kabo e phahameng ea khatello, e leng se etsang hore li-flange tsena li lokele haholo likepe tse nang le khatello e phahameng, li-heat exchanger, li-reactor le likhokahano tsa bohlokoa tsa liphaephe moo ho hanyetsa mokhathala le ts'epo ea nako e telele li leng tsa bohlokoa. Bokhoni ba rona ba ho iketsetsa bo fetola litlhaloso tse tloaelehileng tsa flange hore e be litharollo tse entsoeng ka morero tse sebetsanang le lits'ebetso tse thata ka ho fetisisa tsa indasteri.

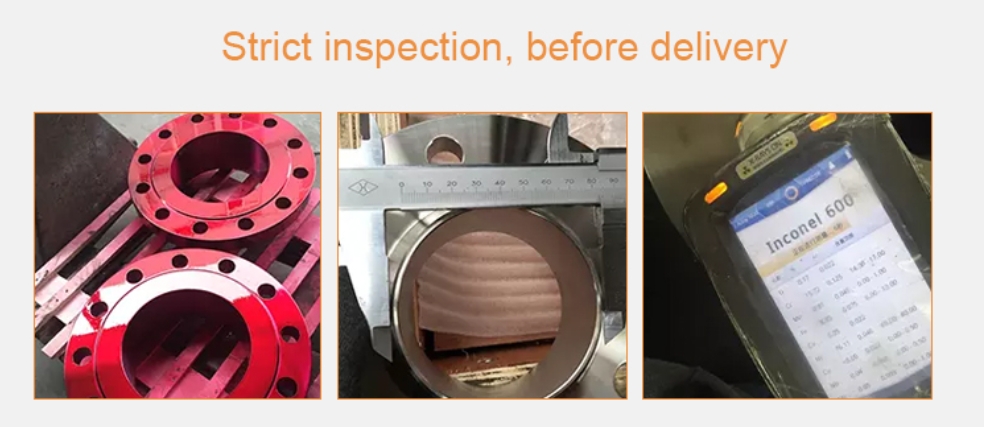

Taolo ea Boleng bakeng sa Likarolo tse Ikhethileng:

Netefatso ea Moralo: Netefatso ea moralo oa motho oa boraro bakeng sa lits'ebetso tsa bohlokoa

Teko ea mohlala: Ho etsoa ha likotoana tsa liteko bakeng sa thepa le netefatso ea ts'ebetso

NDT e Tsoetseng Pele: UT, TOFD, le radiography ea dijithale e arotsoeng ka mekhahlelo bakeng sa li-geometri tse rarahaneng

Netefatso ea Dimensional: Ho skena ka laser le tekanyo ea 3D bakeng sa liprofaele tse ikhethileng

TLHAHISO EA LIHLAHISOA TLHAHISO

Bokgoni ba Tlhahiso bo Tsoetseng Pele:

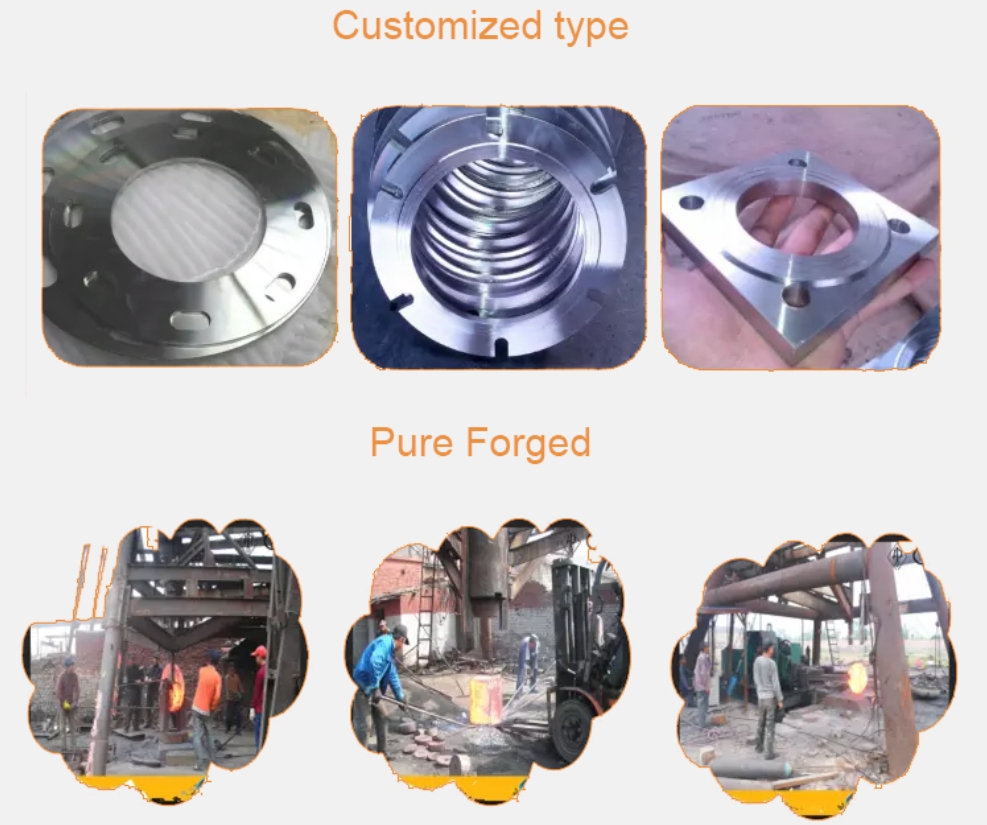

Ho qapa: Ho qapa ka ho koala bakeng sa sebopeho se setle sa lijo-thollo lits'ebetsong tse nang le khatello e phahameng

Tlhahiso ea Poleiti: Bakeng sa li-flange tse kholo moo ho betla ho sa sebetseng

Ho koahela/Ho koahela: Ho koahela ka welding ea li-alloy tse sa senyeheng ke mafome motheong oa tšepe ea carbon

Ho Sebetsa ka ho Nepahetseng: Ho Sebetsa ka ho ...

Phekolo ea Mocheso: Lipotoloho tsa mocheso tse ikhethileng (ho normalizing, ho tima, ho tempering) ka litlhoko tsa thepa

HO TSHWAYA LE HO PHAKA

Sekoti se Matla: Dikreiti tsa lehong tse entsweng ka boenjiniere tse nang le sekoti sa kahare se ikgethileng

Tšireletso ea ho senyeha: Sekoahelo sa VCI, litsamaiso tsa desiccant, le liphutheloana tse laoloang ke boemo ba leholimo

Tšireletso ea Bokaholimo: Likoahelo tse ikhethileng bakeng sa libaka tse entsoeng ka mechini le masoba a khoele

Litokisetso tsa ho sebetsana le tsona: Li-lug tse kopantsoeng tsa ho phahamisa le matšoao a bohareng ba matla a khoheli

TLHAHLOBO

Teko ea Netefatso ea Moralo:

Tlhahlobo ea Khatello ea Kelello ea FEA: ANSYS kapa netefatso ea software e lekanang

Teko ea Khatello ea Prototype: Teko ea Hydrostatic/pneumatic ea likarolo tsa sampole

Teko ea ho Ikamahanya le Lintho: Teko ea ts'enyeho libakeng tsa litšebeletso tse etsisitsoeng

Tlhahlobo ea Mokhathala: Ketsiso ea ho jarisa ka potoloho bakeng sa maemo a ts'ebeletso a matla

Mokhoa oa Tlhahiso

| 1. Khetha thepa e tala ea 'nete | 2. Seha thepa e tala | 3. Ho futhumatsa pele ho nako |

| 4. Ho betla | 5. Kalafo ea mocheso | 6. Mechini e Mebe |

| 7. Ho cheka | 8. Ho lokisa ka hloko | 9. Ho tšoaea |

| 10. Tlhahlobo | 11. Ho paka | 12. Phano |

Kopo

Offshore & Subsea: Likhokahano tse ngata, li-flange tsa sefate sa Keresemese, likhokahano tse phahamisang

Tlhahiso ea Motlakase: Li-flange tsa sistimi ea mantlha ea nyutlelie, litsamaiso tsa turbine bypass

Petrochemical: Li-flange tsa reactor tse nang le khatello e phahameng, likhokahano tsa sebōpi sa reformer

Tšebeletso ea Cryogenic: Libaka tsa ho nosetsa le ho lokisa khase ea LNG

Merafo le Diminerale: Ditsamaiso tsa autoclave le digester tse nang le kgatello e phahameng

Tšebeletso ea rona ea flange ea LWN e etselitsoeng motho ka mong e emela ho feta tlhahiso feela - ke mokhoa oa tšebelisano-'moho oa ho rarolla liphephetso tse rarahaneng tsa boenjiniere. Re sebetsa haufi-ufi le lihlopha tsa hau tsa boenjiniere ho nts'etsapele litharollo tse sa fihlelleng litlhaloso feela empa li ntlafatsa ts'ebetso, li fokotsa litšenyehelo tsa potoloho ea bophelo, le ho netefatsa ts'epo ea nako e telele lits'ebetsong tse thata ka ho fetisisa tsa indasteri lefatšeng.

P: Na o ka amohela TPI?

K: E, ehlile. Rea u amohela etela fektheri ea rona 'me u tle mona ho tla hlahloba thepa le ho hlahloba ts'ebetso ea tlhahiso.

P: Na o ka fana ka Foromo e, Setifikeiti sa tšimoloho?

A: E, re ka fana ka.

P: Na o ka fana ka invoice le CO ho chamber of commerce?

A: E, re ka fana ka.

P: Na o ka amohela L/C e diehisitsweng matsatsi a 30, 60, kapa 90?

K: Re ka khona. Ka kopo buisana le thekiso.

P: Na o ka amohela tefo ya O/A?

K: Re ka khona. Ka kopo buisana le thekiso.

P: Na o ka fana ka disampole?

K: E, disampole tse ding ke mahala, ka kopo sheba le thekiso.

P: Na o ka fana ka dihlahiswa tse dumellanang le NACE?

K: E, re ka khona.

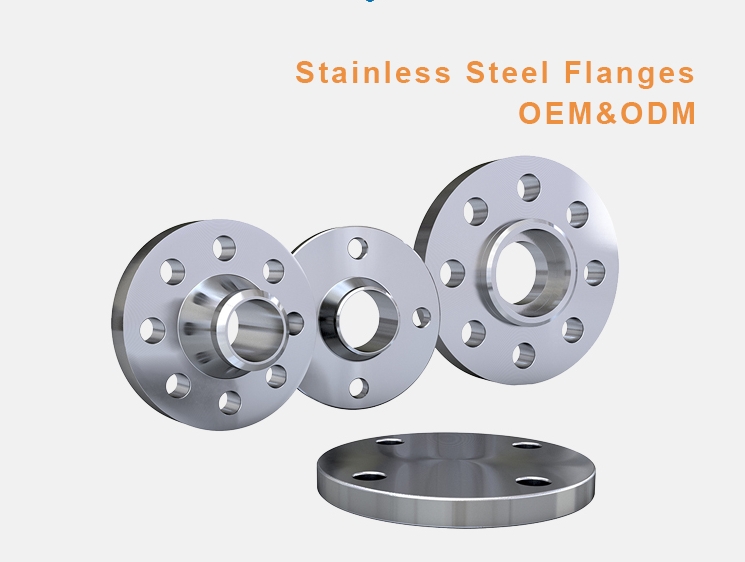

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-PPR tris li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le li-elbow tsa tšepe ea alloy li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Liphaephe tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koentsha Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.

-

Din dn800 flange en10921 pn40 pn6 tšepe ea k'habone ...

-

ANSI DIN Forged Class150 Stainless Steel Slip o ...

-

Letlalo la Flange la Tube le sa Tloaelehang le Ikhethileng ...

-

Flange ea orifice ea asme b16.36 e entsoeng ka Jack ...

-

ASME B 16.5 CS SA 105N LWNFF 20inch 600LB LWN F...

-

Sekere sa BSP DIN PN 10/16 tšepe ea carbon A105 flange ...