DN800 DIN EN1092-1 PN40/PN6 Tšepe ea Khabone Weld Neck Flange

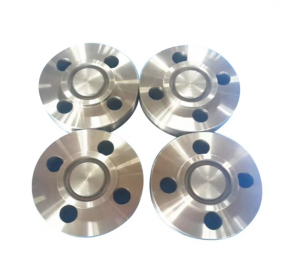

Flange ea DN800 DIN EN1092-1 PN40/PN6 Carbon Steel Weld Neck e emela karolo ea bohlokoa lits'ebetsong tsa liphaephe tse bophara bo boholo tse hlokang botšepehi bo phahameng ba sebopeho le ts'ebetso e tšepahalang ea ho tiisa. E entsoe ho latela maemo a Europe, flange ena e entsoe bakeng sa lits'ebetso tsa khatello e phahameng lits'ebetsong tsa indasteri, e kopanya matla a matla a tšepe ea carbon le machining e nepahetseng ho netefatsa ts'ebetso e ntle maemong a ts'ebeletso a hlokang thuso.

TLHAHISO

| Lebitso la Sehlahisoa | Letheka le kopaneng/Flange e lokolohileng |

| Boholo | 1/2"-24" |

| Khatello | 150#-2500#,PN0.6-PN400,5K-40K |

| E tloaelehileng | ANSI B16.5,EN1092-1, JIS B2220 joalo-joalo. |

| Qetello ea sekoti | MSS SP 43, ASME B16.9 |

| Thepa | Ts'epe e sa beng le mabali:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo le tse ding. |

| Tšepe ea k'habone:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 jj. | |

| Tšepe e sa ruseng habeli:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 le tse ding. | |

| Tšepe ea liphaephe:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 jj. | |

| motsoako oa nikeli:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 jj. | |

| Motsoako oa Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, jj. | |

| Kopo | Indasteri ea peterole; indasteri ea lifofane le lifofane; indasteri ea meriana; mosi oa khase; setsi sa motlakase; mohaho oa likepe; kalafo ea metsi, jj. |

| Melemo | setoko se loketse, nako ea ho fana ka potlako; e fumaneha ka boholo bohle, e etselitsoe; boleng bo holimo |

E hahiloe ka tšepe ea carbon ea boleng bo holimo ea P265GH, flange ena ea molala oa weld e fana ka thepa e ikhethang ea mechini ho kenyeletsoa matla a fokolang a tlhahiso ea 265 MPa le matla a ho thaepa a 410-530 MPa. Sebopeho sa lik'hemik'hale se laoloang ka hloko sa thepa se fana ka ho thaepa ho hoholo, ho hanyetsa mafome, le ho tšoarella ho pholletsa le mocheso ho tloha ho -20°C ho isa ho +400°C.

MAEMO A DIMENSION

TLHAHISO EA LIHLAHISOA TLHAHISO

E lumellana le litlhaloso tsa DIN EN1092-1, flange ena e fihlela maemo a thata a boleng ba Europe bakeng sa lisebelisoa tsa khatello. Tekanyetso ea PN40 e bontša matla a khatello a tloaelehileng a 40 bar ho 120°C, ha mofuta oa PN6 o fana ka litharollo tse theko e tlaase bakeng sa lits'ebetso tsa khatello e tlase. Litlhophiso tsena ka bobeli li boloka ho nepahala ha boholo ka har'a limaraka tsa mamello ea ISO, ho netefatsa ho lumellana ho se nang sekoli le litsamaiso tsa liphaephe tsa lefats'e.

HO TSHWAYA LE HO PHAKA

Flange e 'ngoe le e 'ngoe ea DN800 e kenngoa ka har'a sephutheloana se sireletsang se qalang ka sekoahelo sa VCI (Vapor Corrosion Inhibitor) ho thibela ho bola nakong ea ho tsamaea. Sephutheloana sa polasetiki se boima se fana ka tšireletso ea mantlha, ha foam e khaotsoeng ka mokhoa o ikhethileng e sireletsa libaka tse entsoeng ka mechini le masoba a liboutu. Likreite tsa lehong tse nang le foreimi e matlafalitsoeng li netefatsa botšepehi ba sebopeho nakong ea ho romelloa ha thepa machabeng, ka kabo e nepahetseng ea boima le libaka tsa ho phahamisa tse tšoailoeng ka ho hlaka bakeng sa ts'ebetso e sireletsehileng.

Ts'ebetso ea rona ea ho romella thepa e kenyelletsa mekhoa e ikhethileng ea ho sebetsana le thepa bakeng sa likarolo tse kholo. Flange ka 'ngoe e fumana matšoao a kamehla a boitsebahatso ho kenyeletsoa le sehlopha sa thepa, palo ea mocheso, le tekanyo ea khatello bakeng sa taolo e bonolo ea thepa. Re ntlafatsa ho jara ha lijana ho eketsa tšebeliso ea sebaka ha re ntse re netefatsa kabo e nepahetseng ea boima, ka litokomane tse qaqileng tsa ho romella thepa ho kenyeletsoa le manane a ho paka, litifikeiti tsa boima, le litaelo tsa ho sebetsana le thepa tse tsamaeang le thomello e 'ngoe le e 'ngoe.

TLHAHLOBO

Flange e 'ngoe le e 'ngoe e feta liprothokholong tse matla tsa liteko tse qalang ka tlhahlobo ea ultrasound ho lemoha liphoso tsa ka hare. Netefatso ea litekanyo e sebelisang litsamaiso tsa tekanyo ea laser e netefatsa ho latela mamello ea EN1092-1, ha tlhahlobo ea hydrostatic ka khatello e lekantsoeng ka makhetlo a 1.5 e netefatsa bokhoni ba ho thibela khatello. Setifikeiti sa thepa se kenyelletsa tlhahlobo e felletseng ea lik'hemik'hale le tlhahlobo ea thepa ea mechini ka ho latela ka botlalo ho tloha thepa e tala ho ea sehlahisoa se felileng.

Mokhoa oa Tlhahiso

| 1. Khetha thepa e tala ea 'nete | 2. Seha thepa e tala | 3. Ho futhumatsa pele ho nako |

| 4. Ho betla | 5. Kalafo ea mocheso | 6. Mechini e Mebe |

| 7. Ho cheka | 8. Ho lokisa ka hloko | 9. Ho tšoaea |

| 10. Tlhahlobo | 11. Ho paka | 12. Phano |

Nyeoe ea Tšebelisano-'moho

Projeke e Turkey, di-flange di sebediswa diphaepheng tsa kgase ya tlhaho. Di-flange tseo kaofela di amohetswe ke TUV.

LEQEPHE LA DITATA LA FLANGE

1Litekanyo tsa Flange le mamello li tla ba ho latela ASME B16.5.

2. Li-flange li lokela ho hlahisoa ka ho betla.

3. Thepa e tla ba ho latela maemo a ASTM A105, ASTM A694 F65 le ASTM A694 F70.

4. Li-flange tsa ASTM A694 F65 le ASTM A694 F70 li lokela ho tingoa le ho halefisoa.

5. Lisetifikeiti tsa teko ea thepa le litlaleho tsa kalafo ea mocheso li tla fumaneha bakeng sa tlhahlobo ea TPI.

6. Li-flange tsa WN li lokela ho ba le lipheletso tsa bevel tse lumellanang le ASME B16.25.

7. Litekanyetso tsa liteko tsa lik'hemik'hale le tsa mechine (tšusumetso, chai, ho tenyetseha jj.) li tla latela maemo a amanang.

8. Libaka tsohle li lokela ho khabisoa ka mochini le ho penta ka varnish ka oli e bonaletsang ho thibela ho rusa.

9. Ho tshwaya ho tla kenyeletsa tlhahisoleseding e latelang,

• Bophara (nako e fedileng 6”)

• Sehlopha sa kgatello (nako e fedileng ke 150 LB)

• Sehlopha sa thepa (nako e fedileng ke ASTM A 105)

• Botenya ba lebota (nako e fedileng ke 4,78 mm)

• Nomoro ea Mocheso (e felloa ke nako 138413)

• Maemo a tlhahiso (ASME B16.5)

10. Thepa e lokela ho se be le diphoso le mapetso a bokaholimo. Litokiso tsa ho tjheseletsa di thibetswe ka thata.

11. Li-flange tsohle li lokela ho phahamisoa sefahlehong (RF) ka bokaholimo ba ho koala. Bokaholimo ba ho koala e lokela ho ba Ra 3,2 - 6,3 µm (125 - 250 mic. inc.) ho ea ho ASME B46.1.

12. Thepa e lokela ho pakoa ho thibela tshenyo hodima machining le ho kwala bokahodimo.

13. Litekanyo tsohle li tla ba ka mamello e ntle (+). Tolerances e fokolang e thibetsoe ka thata.

14. Li-bevelling tsa Flange li lokela ho etsoa hore li lumellane le ASME B16.25.

15. Tshebetso ea tlhahiso e tla hlahlojoa neng kapa neng ke TPI.

16. TPI e ka nka disampole ho tsoa thepa efe kapa efe bakeng sa sampole ea teko ea lik'hemik'hale/mechanical.

17. Tlaleho ea tlhahlobo e tlang e tla hlahlojoa ke TPI.

| Ntho | Boholo (Inchi) | Sehlopha sa Khatello | CS | Thepa | Boima ba 'mele (mm) | Sebaka | Bongata. |

| SORF | 12 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 32 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 14 | LIFANGE TSA TANK | 2 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 5.54 | LIFANGE TSA TANK | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 6 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 5.54 | LIFANGE TSA TANK | 8 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 14 | LIFANGE TSA TANK | 8 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 16 | LIFANGE TSA TANK | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 6 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 5.54 | LIFANGE TSA TANK | 8 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 14 | LIFANGE TSA TANK | 16 |

| Ntho | Boholo (Inchi) | Sehlopha sa Khatello | CS | Thepa | Boima ba 'mele (mm) | Sebaka | Bongata. |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Molala oa Weld | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Molala oa Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Molala oa Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Molala oa Weld | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Molala oa Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Molala oa Weld | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Molala oa Weld | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Molala oa Weld | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Molala oa Weld | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Molala oa Weld | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Molala oa Weld | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

Lenaneo la rona la netefatso ea boleng le akaretsa taolo ea ts'ebetso ea lipalo-palo nakong eohle ea tlhahiso, ka liteko tsa sehlopha bakeng sa netefatso ea botsitso. Tlhahlobo ea ho qetela e kenyelletsa tlhahlobo ea pono bakeng sa liphoso tsa bokaholimo, netefatso ea ho nepahala ha litekanyo, le netefatso ea matšoao. Lirekoto tsohle tsa boleng li bolokoa bonyane lilemo tse 10, ho netefatsa hore ho latela ka botlalo le ho latela maemo a boleng a machaba.

LBH

1. Mefuta e fapaneng ea lisebelisoa tsa tšepe e sa hloekang ke efe?

Karabo: Lisebelisoa tsa liphaephe tsa tšepe e sa ruseng li kenyelletsa lisebelisoa tsa liphaephe tsa ho tjheseletsa li-butt, lisebelisoa tsa liphaephe tsa ho tjheseletsa li-socket, lisebelisoa tsa liphaephe tse nang le khoele, li-flange, li-valve le mefuta e meng.

2. Phapang ke efe pakeng tsa di-fitting tsa diphaephe tsa tshepe e sa ruseng ya 304 le 316 tsa tshepe e sa ruseng?

A: Tšepe e sa hloekang ea 304 e loketse lits'ebetso tse ngata 'me e na le khanyetso e ntle ea mafome. Ka lehlakoreng le leng, tšepe e sa hloekang ea 316 e na le khanyetso e betere ea mafome libakeng tse senyang haholo 'me e loketse haholoanyane lits'ebetso tsa leoatleng le tsa lik'hemik'hale.

3. Melemo ea ho sebelisa liphaephe tse kopantsoeng ka forged butt ke efe?

K: Di-fitting tsa ho weld tsa mokoko tse entsweng ka ho tjheseletsa di fana ka matla a ntlafetseng, botshepehi le dikgokelo tse se nang ho dutla. Di fana ka kganyetso e ntle ya tshusumetso mme di kgethwa bakeng sa tshebediso ya kgatello e phahameng le mocheso o phahameng.

4. Flange ea ho tjheseletsa ea marago ke eng?

Karabo: Flange ea ho welding ea butt ke flange ea phaephe e nang le hub e telele e nang le tapered 'me e hoketsoe phaepheng. E fana ka phetoho e boreleli ho tloha phaepheng ho ea ho flange ka matla le botšepehi bo babatsehang.

5. Ke sehlopha sefe sa tšepe e sa ruseng se sebelisoang hangata bakeng sa li-fitting tsa liphaephe?

A: Mekhahlelo ea tšepe e sa ruseng 304, 316, 304L, 316L le 317 e sebelisoa hangata liphaepheng ka lebaka la ho hanyetsa mafome hantle, ho tšoarella le ho tenyetseha ha tsona.

6. Na disebediswa tsa diphaephe tsa tshepe e sa ruseng di ka sebediswa ditshebedisong tsa mocheso o phahameng?

Karabo: E, disebediswa tsa tshepe e sa ruseng di loketse tshebediso ya mocheso o phahameng. Leha ho le jwalo, sehlopha sa tshepe e sa ruseng e sebediswang se lokela ho kgethwa ka hloko ho latela ditlhoko tse ikgethang tsa mocheso wa tshebediso.

7. Na diphaephe tsa tšepe e sa ruseng di loketse indasteri ya dijo le dino?

Karabo: E, diphaephe tsa tšepe e sa ruseng di sebediswa haholo indastering ya dijo le dino ka lebaka la bohloeki ba tsona, ho hanyetsa mafome le tlhokomelo e bonolo.

8. Phapang ke efe pakeng tsa di-socket welding fittings le di-butt welding fittings?

Karabo: Di-fitting tsa phaephe tse welded ka soketeng di kenya phaephe ka hara sokete ebe di etsa welding ya fillet ho hokela phaephe. Di-fitting tsa weld tsa butt, ka lehlakoreng le leng, di hloka hore dipheletso tsa phaephe di beveled ebe di welded.

9. Na disebediswa tsa diphaephe tsa tshepe e sa ruseng di ka sebediswa hape?

K: E, diphaephe tsa tšepe e sa ruseng di ka sebediswa hape haholo. Tshepe e sa ruseng ke thepa e tsitsitseng e ka sebediswang hape le ho sebediswa hape ntle le ho lahlehelwa ke thepa kapa boleng ba yona.

10. Melemo ea ho sebelisa liphaephe tsa tšepe e sa ruseng ke efe ha e bapisoa le lisebelisoa tse ling?

K: Lisebelisoa tsa liphaephe tsa tšepe e sa ruseng li fana ka melemo e mengata, joalo ka ho hanyetsa mafome hantle, matla a phahameng, ho tšoarella le thepa ea bohloeki. Ha li hloke tlhokomelo e ngata, li phela nako e telele 'me li na le ponahalo e hloekileng le e ntle.

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-PPR tris li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le li-elbow tsa tšepe ea alloy li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Liphaephe tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koentsha Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.

-

Sekere sa BSP DIN PN 10/16 tšepe ea carbon A105 flange ...

-

Custom High Quality 304 Stainless Steel Flanged Flanged ...

-

Sefahla sa sefahleho se phahamisitsoeng sa ho tjheseletsa tšepe EN1092-1 type0 ...

-

ASME B16.5 BL RF ASTM A182 F316L Stainless stee ...

-

Soketeng welded flange A105 k'habone tšepe SW RTJ 3/4 ...

-

Tšepe ea Khabone e entsoeng ka ASME b16.36 wn orifice flan ...