Flange ea Orifice ea ASME B16.36 WN e entsoeng ka Jack Screw

Flange ea Forged ASME B16.36 Weld Neck Orifice Flange e nang le Jack Screw e emela karolo ea tekanyo ea phallo e entsoeng ka nepo e etselitsoeng lits'ebetso tsa bohlokoa tsa ts'ebetso ho pholletsa le makala a indasteri a hlokang thuso. Flange ena e ikhethang e kopanya theknoloji e tsoetseng pele ea forging le likarolo tsa moralo tse sebetsang ho netefatsa ts'ebetso e nepahetseng, e tšepahalang le e sireletsehileng lits'ebetsong tsa khatello e phahameng le mocheso o phahameng. E entsoe ka ho latela ka tieo litekanyetso tsa ASME B16.36 le B16.5, e sebetsa e le karolo ea bohlokoa lits'ebetsong tsa tekanyo le taolo ea mokelikeli.

TLHAHISO

| Lebitso la Sehlahisoa | tjheseletsa molaleng oa Orifice flange | |||

| SAESE | 1" holimo ho 24" | |||

| Khatello | 150#-2500# | |||

| E tloaelehileng | ANSI B16.36 | |||

| Botenya ba lebota | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS joalo-joalo. | |||

| Thepa | Tšepe e sa ruseng: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H,A182F316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo le jj. Tšepe ea k'habone: A105, A350LF2, Q235, St37, St45.8, A42CP, E24, A515 Gr60, A515 Gr 70 | |||

| Tšepe e sa ruseng habeli: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 le jj. Tšepe ea phaephe: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 jj. | ||||

| Motsoako oa nikeli: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 jj. Motsoako oa Cr-Mo: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3 jj. | ||||

| Kopo | Indasteri ea peterole; indasteri ea polokelo le ea lifofane; indasteri ea meriana; mosi oa khase; feme ea motlakase; moaho oa likepe; kalafo ea metsi, jj. | |||

| Melemo | setoko se loketse, nako ea ho fana ka potlako; e fumaneha ka boholo bohle, e etselitsoe; boleng bo holimo | |||

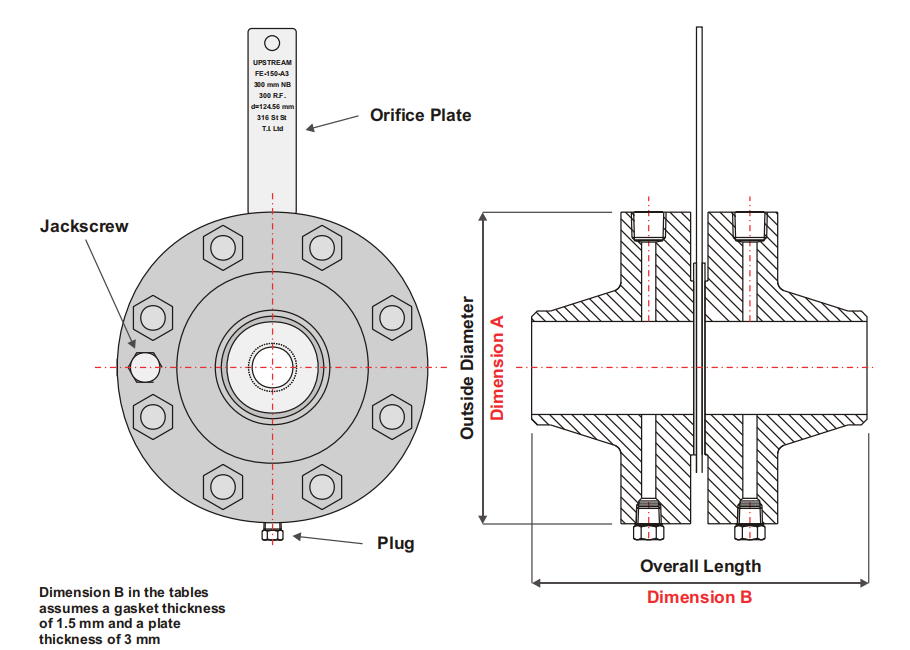

MAEMO A DIMENSION

TLHAHISOLESELING EA LIHLAHISOA

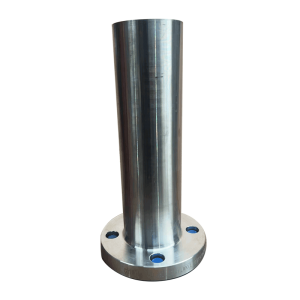

1. Sebopeho sa Molala oa Weld

Moralo o atolositsoeng oa setsi se tenyetsehang bakeng sa kabo e ntle ea khatello ea maikutlo

Phetoho e boreleli ho tloha ho flange ho ea ho phaephe e fokotsa moferefere

Botšepehi bo ntlafalitsoeng ba sebopeho bakeng sa lits'ebetso tse nang le khatello e phahameng

2. Sistimi e Kopaneng ea Jack Screw

Bonyane dikurufu tse pedi tsa jack (tse arohaneng ka 90°, dikurufu tse ding di a fumaneha bakeng sa boholo bo boholo)

Masoba a tloaelehileng a ½"-13 a UNC a nang le khoele (litlhaloso tse ling tsa khoele lia fumaneha)

E nolofalletsa ho kenngoa le ho tlosoa ha poleiti ea orifice e sireletsehileng ntle le ho qhaqhoa ha sistimi

E thibela tšenyo ea sefahleho sa flange nakong ea ts'ebetso ea tlhokomelo

3. Ho nepahala ha Orifice Bore

E entsoe ka mechini ho latela mamello e tiileng ea litekanyo (± 0.001" standard)

Qetello ea bokaholimo bo boreleli (Ra ≤ 63 µin)

Ho tsepamisa mohopolo ho bolokiloe ka hare ho 0.005" TIR

4. Moralo oa Sefahleho se Hōlisitsoeng

Sefahleho se tloaelehileng se phahamisitsoeng sa 1/16" (RF) se nang le qetello e nang le meno (125-250 AARH)

Mefuta e meng ea sefahleho e fumaneha (FF, RTJ, T&G)

Tshebetso e ntle ea ho hatella le ho tiisa gasket

HO TSHWAYA LE HO PHAKA

Sephutheloana se Sireletsang

Ho phuthela ka polasetiki ka bomong ka tšireletso ea VCI

Likereiti tsa lehong tse nang le tšehetso e nepahetseng bakeng sa ho romelloa ha thepa linaheng tse ling

Li-cap tse sireletsang bakeng sa likhoele tsa screw tsa jack

Ho hlaka ha boitsebahatso le ho tšoaea ho latela litlhoko tsa ASME

Litokomane tsa Thomello

Lenane la li-invoice tsa khoebo le lethathamo la ho paka

Setifikeiti sa tšimoloho

Sephutheloana sa setifikeiti sa thepa

Litlaleho tsa liteko tsa fektheri le litifikeiti tsa tlhahlobo

TLHAHLOBO

1. Netefatso ea Lintho tse bonahalang

Tlhahlobo ea spectrochemical

Teko ea thepa ea mechini (ho tsitlella, ho ikatisa, ho lelefatsa)

Teko ea tšusumetso ea Charpy bakeng sa lits'ebetso tsa mocheso o tlase

2. Tlhahlobo e sa Senyeheng

Teko ea ho Kena ha Metsi (PT) ho latela ASME Sec V Athikele ea 6

Teko ea Lik'hemik'hale tsa Magnetic (MT) bakeng sa thepa ea ferritic

Teko ea Ultrasonic (UT) bakeng sa liphoso tsa ka hare

Teko ea ho thatafala likarolong tse mahlonoko

3. Netefatso ea litekanyo

Tlhahlobo ea 100% ka ASME B16.36

Netefatso ea bophara ba mokoti le ho netefatsa ho teba ha oona

Tiisetso ea selikalikoe sa lesoba la bolt le mokhoa oa ho phunya

Litekanyo tsa botenya le ho batalla ha sefahleho

Nyeoe ea Tšebelisano-'moho

Flange ea Forged ASME B16.36 WN Orifice e nang le Jack Screw e emela sehlohlolo sa boenjiniere bo tsoetseng pele ba tšepe, tlhahiso e nepahetseng, le boqapi ba moralo bo sebetsang. Karolo ka 'ngoe e etsoa ka tlhokomelo e sa sekisetseng ho lintlha tse qaqileng, e netefatsang ts'ebetso e tšepahalang maemong a ts'ebetso a thata ka ho fetisisa. Boitlamo ba rona ba boleng, hammoho le boiphihlelo ba lilemo tse mashome indastering, bo etsa hore li-flange tsena e be khetho e ratoang bakeng sa baenjiniere le basebetsi lefatšeng ka bophara ba batlang ho nepahala, ho tšepahala le polokeho litsamaisong tsa bona tsa ho lekanya phallo.

Mokhoa oa Tlhahiso

| 1Khetha thepa e tala ea 'nete | 2. Seha thepa e tala | 3. Ho futhumatsa pele ho nako |

| 4. Ho betla | 5. Kalafo ea mocheso | 6. Mechini e Mebe |

| 7. Ho cheka | 8. Ho lokisa ka hloko | 9. Ho tšoaea |

| 10. Tlhahlobo | 11. Ho paka | 12. Phano |

Re hlahisa di-flange tsa rona tsa orifice tse welded ka hara marago tsa boleng bo hodimo, tse etseditsweng ho fihlela ditlhoko tse hlokahalang tsa mefuta e fapaneng ya ditshebediso tsa indasteri. Di-flange tsa rona tsa orifice di etseditswe ho fana ka ditharollo tse tshepahalang le tse sebetsang hantle bakeng sa ho lekanya phallo ya metsi, dikgase le mouwane diphaepheng.

Li-flange tsa rona tsa orifice tsa weld tsa butt li entsoe ka thepa ea boleng bo holimo 'me li fana ka ho tšoarella ho ikhethang le ho hanyetsa mafome, e leng se etsang hore li lokele ho sebelisoa libakeng tse thata le tse senyang. Ho sebetsa hantle ha flange ho netefatsa hore e lekana hantle ebile e tiisa ka thata, ho fokotsa kotsi ea ho lutla le ho netefatsa ts'ebetso ea nako e telele.

Moralo oa molala o kopantsoeng oa li-flange tsa rona tsa orifice o etsa khokahano e matla le e sireletsehileng tsamaisong ea liphaephe bakeng sa botsitso le tšehetso e ntlafalitsoeng. Moralo ona o boetse o thusa ho fokotsa khatello ea maikutlo likhokahanong tsa flange, ka hona o ntlafatsa botšepehi ba sistimi ka kakaretso.

Li-flange tsa rona tsa orifice li fumaneha ka boholo bo fapaneng le litekanyetso tsa khatello ho fihlela litlhoko tse fapaneng tsa ts'ebeliso. Ebang li sebelisoa indastering ea oli le khase, petrochemical, ts'ebetso ea lik'hemik'hale kapa tlhahiso ea motlakase, li-flange tsa rona tsa orifice tsa molala oa weld li fana ka tekanyo e tsitsitseng le e nepahetseng ea phallo.

Ntle le kaho ea tsona e tiileng, li-flange tsa rona tsa orifice li bonolo ho li kenya le ho li hlokomela, li boloka nako le lisebelisoa tsa bohlokoa ho bareki ba rona. Qetello ea bokaholimo bo boreleli le litekanyo tse nepahetseng li ntlafatsa boiketlo ba ho sebetsana le ho kopanya.

Re utloisisa karolo ea bohlokoa eo li-flange tsa li-orifice plate li e bapalang ho netefatseng katleho le polokeho ea lits'ebetso tsa indasteri. Ke ka lebaka leo re ikemiselitseng ho fana ka lihlahisoa tse fihlelang maemo a boleng bo holimo le litlhaloso tsa ts'ebetso.

Ka di-flange tsa rona tsa orifice tsa ho weld butt, o ka tshepa hore ditshebediso tsa hao tsa ho lekanya phallo di tla rua molemo tshebetsong e tshepahalang, e nkang nako e telele le e nepahetseng. Latsoa phapang ka di-flange tsa rona tsa orifice tsa orifice tsa butt weld tse hodimo mme o eketse bokgoni ba tshebetso ya hao.

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-tri tsa PPR li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le litsoe tsa tšepe e kopantsoeng li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Li-fitting tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koetlisetsa Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.

-

Long Weld Neck Flange Tloaelehileng ea Khatello LWN Bakeng sa ...

-

Sekhahla se Tloaelehileng sa Khatello ea Orifice Flange se Thehiloeng ...

-

ANSI DIN Forged Class150 Stainless Steel Slip o ...

-

Moetsi ea khethehileng ea ho betla khatello e phahameng ...

-

DIN ANSI 150LB PN16 tšepe e sa ruseng 304 316 316 ...

-

Tšepe e sa hloekang 304 304L 316 316L ASTM e entsoeng ka ...