TLHAHISO

| Lebitso la Sehlahisoa | Letheka le kopaneng/Flange e lokolohileng |

| Boholo | 1/2"-24" |

| Khatello | 150#-2500#,PN0.6-PN400,5K-40K |

| E tloaelehileng | ANSI B16.5,EN1092-1, JIS B2220 joalo-joalo. |

| Qetello ea sekoti | MSS SP 43, ASME B16.9 |

| Thepa | Ts'epe e sa beng le mabali:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo le tse ding. |

| Tšepe ea k'habone:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 jj. | |

| Tšepe e sa ruseng habeli:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 le tse ding. | |

| Tšepe ea liphaephe:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 jj. | |

| motsoako oa nikeli:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 jj. | |

| Motsoako oa Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, jj. | |

| Kopo | Indasteri ea peterole; indasteri ea lifofane le lifofane; indasteri ea meriana; mosi oa khase; setsi sa motlakase; mohaho oa likepe; kalafo ea metsi, jj. |

| Melemo | setoko se loketse, nako ea ho fana ka potlako; e fumaneha ka boholo bohle, e etselitsoe; boleng bo holimo |

MAEMO A DIMENSION

TLHAHISO EA LIHLAHISOA TLHAHISO

1. Sefahleho

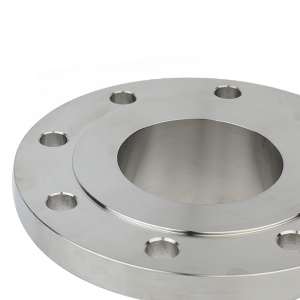

E ka phahamisoa sefahleho (RF), sefahleho se felletseng (FF), Lenonyello la Ring (RTJ), Groove, Leleme, kapa e etselitsoe uena.

2.Bevel e qetellang ho ya ka ANSI B16.25

3.CNC e felile hantle.

Qetello ea sefahleho: Qetello e ka lehlakoreng la flange e lekanngoa e le Bophahamo ba Average Roughness ba Arithmetical (AARH). Qetello e khethoa ke maemo a sebelisoang. Mohlala, ANSI B16.5 e bolela liqetello tsa sefahleho ka har'a sebaka sa 125AARH-500AARH (3.2Ra ho isa ho 12.5Ra). Liqetello tse ling li fumaneha ka kopo, mohlala 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra kapa 6.3/12.5Ra. Sebaka sa 3.2/6.3Ra se atile haholo.

HO TSHWAYA LE HO PHAKA

• Lera ka leng le sebelisa filimi ea polasetiki ho sireletsa bokaholimo

• Bakeng sa tšepe e sa ruseng kaofela e pakoa ka lebokose la plywood. Bakeng sa flange ea carbon e kholo e pakoa ka pallet ea plywood. Kapa e ka etsoa ka mokhoa o ikhethileng.

• Letšoao la ho romella le ka etsoa ha ho kopuoa

• Matshwao a dihlahiswa a ka betlwa kapa a printwa. OEM e a amoheleha.

TLHAHLOBO

• Teko ea UT

• Teko ea PT

• Teko ea MT

• Teko ea boholo

Pele ho pepa, sehlopha sa rona sa QC se tla hlophisa tlhahlobo ea NDT le tlhahlobo ea boholo. Hape se amohela TPI (tlhahlobo ea motho oa boraro).

Mokhoa oa Tlhahiso

| 1. Khetha thepa e tala ea 'nete | 2. Seha thepa e tala | 3. Ho futhumatsa pele ho nako |

| 4. Ho betla | 5. Kalafo ea mocheso | 6. Mechini e Mebe |

| 7. Ho cheka | 8. Ho lokisa ka hloko | 9. Ho tšoaea |

| 10. Tlhahlobo | 11. Ho paka | 12. Phano |

Nyeoe ea Tšebelisano-'moho

Projeke e Turkey, di-flange di sebediswa diphaepheng tsa kgase ya tlhaho. Di-flange tseo kaofela di amohetswe ke TUV.

LEQEPHE LA DITATA LA FLANGE

1Litekanyo tsa Flange le mamello li tla ba ho latela ASME B16.5.

2. Li-flange li lokela ho hlahisoa ka ho betla.

3. Thepa e tla ba ho latela maemo a ASTM A105, ASTM A694 F65 le ASTM A694 F70.

4. Li-flange tsa ASTM A694 F65 le ASTM A694 F70 li lokela ho tingoa le ho halefisoa.

5. Lisetifikeiti tsa teko ea thepa le litlaleho tsa kalafo ea mocheso li tla fumaneha bakeng sa tlhahlobo ea TPI.

6. Li-flange tsa WN li lokela ho ba le lipheletso tsa bevel tse lumellanang le ASME B16.25.

7. Litekanyetso tsa liteko tsa lik'hemik'hale le tsa mechine (tšusumetso, chai, ho tenyetseha jj.) li tla latela maemo a amanang.

8. Libaka tsohle li lokela ho khabisoa ka mochini le ho penta ka varnish ka oli e bonaletsang ho thibela ho rusa.

9. Ho tshwaya ho tla kenyeletsa tlhahisoleseding e latelang,

• Bophara (nako e fedileng 6”)

• Sehlopha sa kgatello (nako e fedileng ke 150 LB)

• Sehlopha sa thepa (nako e fedileng ke ASTM A 105)

• Botenya ba lebota (nako e fedileng ke 4,78 mm)

• Nomoro ea Mocheso (e felloa ke nako 138413)

• Maemo a tlhahiso (ASME B16.5)

10. Thepa e lokela ho se be le diphoso le mapetso a bokaholimo. Litokiso tsa ho tjheseletsa di thibetswe ka thata.

11. Li-flange tsohle li lokela ho phahamisoa sefahlehong (RF) ka bokaholimo ba ho koala. Bokaholimo ba ho koala e lokela ho ba Ra 3,2 - 6,3 µm (125 - 250 mic. inc.) ho ea ho ASME B46.1.

12. Thepa e lokela ho pakoa ho thibela tshenyo hodima machining le ho kwala bokahodimo.

13. Litekanyo tsohle li tla ba ka mamello e ntle (+). Tolerances e fokolang e thibetsoe ka thata.

14. Li-bevelling tsa Flange li lokela ho etsoa hore li lumellane le ASME B16.25.

15. Tshebetso ea tlhahiso e tla hlahlojoa neng kapa neng ke TPI.

16. TPI e ka nka disampole ho tsoa thepa efe kapa efe bakeng sa sampole ea teko ea lik'hemik'hale/mechanical.

17. Tlaleho ea tlhahlobo e tlang e tla hlahlojoa ke TPI.

| Ntho | Boholo (Inchi) | Sehlopha sa Khatello | CS | Thepa | Boima ba 'mele (mm) | Sebaka | Bongata. |

| SORF | 12 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 32 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 14 | LIFANGE TSA TANK | 2 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 5.54 | LIFANGE TSA TANK | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 6 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 5.54 | LIFANGE TSA TANK | 8 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 14 | LIFANGE TSA TANK | 8 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 16 | LIFANGE TSA TANK | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 6 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 5.54 | LIFANGE TSA TANK | 8 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 14 | LIFANGE TSA TANK | 16 |

| Ntho | Boholo (Inchi) | Sehlopha sa Khatello | CS | Thepa | Boima ba 'mele (mm) | Sebaka | Bongata. |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Molala oa Weld | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Molala oa Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Molala oa Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Molala oa Weld | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Molala oa Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Molala oa Weld | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Molala oa Weld | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Molala oa Weld | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Molala oa Weld | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Molala oa Weld | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Molala oa Weld | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

LBH

1. Mefuta e fapaneng ea lisebelisoa tsa tšepe e sa hloekang ke efe?

Karabo: Lisebelisoa tsa liphaephe tsa tšepe e sa ruseng li kenyelletsa lisebelisoa tsa liphaephe tsa ho tjheseletsa li-butt, lisebelisoa tsa liphaephe tsa ho tjheseletsa li-socket, lisebelisoa tsa liphaephe tse nang le khoele, li-flange, li-valve le mefuta e meng.

2. Phapang ke efe pakeng tsa di-fitting tsa diphaephe tsa tshepe e sa ruseng ya 304 le 316 tsa tshepe e sa ruseng?

A: Tšepe e sa hloekang ea 304 e loketse lits'ebetso tse ngata 'me e na le khanyetso e ntle ea mafome. Ka lehlakoreng le leng, tšepe e sa hloekang ea 316 e na le khanyetso e betere ea mafome libakeng tse senyang haholo 'me e loketse haholoanyane lits'ebetso tsa leoatleng le tsa lik'hemik'hale.

3. Melemo ea ho sebelisa liphaephe tse kopantsoeng ka forged butt ke efe?

K: Di-fitting tsa ho weld tsa mokoko tse entsweng ka ho tjheseletsa di fana ka matla a ntlafetseng, botshepehi le dikgokelo tse se nang ho dutla. Di fana ka kganyetso e ntle ya tshusumetso mme di kgethwa bakeng sa tshebediso ya kgatello e phahameng le mocheso o phahameng.

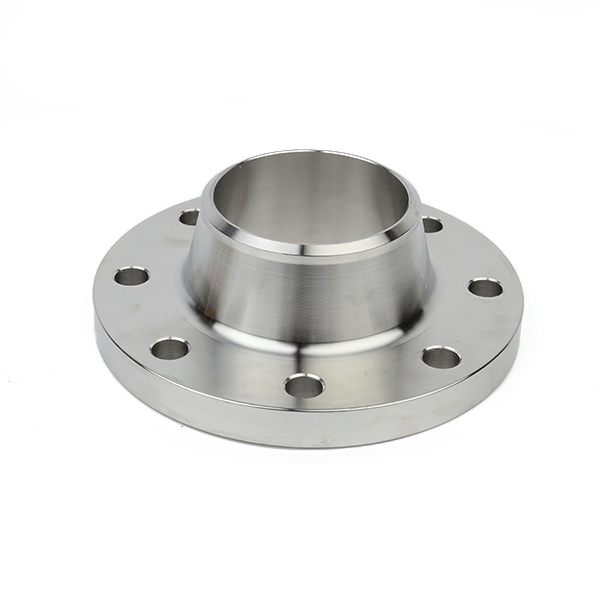

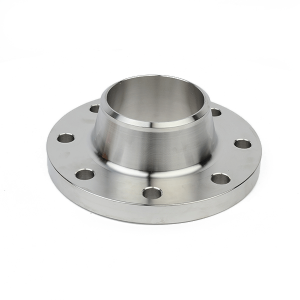

4. Flange ea ho tjheseletsa ea marago ke eng?

Karabo: Flange ea ho welding ea butt ke flange ea phaephe e nang le hub e telele e nang le tapered 'me e hoketsoe phaepheng. E fana ka phetoho e boreleli ho tloha phaepheng ho ea ho flange ka matla le botšepehi bo babatsehang.

5. Ke sehlopha sefe sa tšepe e sa ruseng se sebelisoang hangata bakeng sa li-fitting tsa liphaephe?

A: Mekhahlelo ea tšepe e sa ruseng 304, 316, 304L, 316L le 317 e sebelisoa hangata liphaepheng ka lebaka la ho hanyetsa mafome hantle, ho tšoarella le ho tenyetseha ha tsona.

6. Na disebediswa tsa diphaephe tsa tshepe e sa ruseng di ka sebediswa ditshebedisong tsa mocheso o phahameng?

Karabo: E, disebediswa tsa tshepe e sa ruseng di loketse tshebediso ya mocheso o phahameng. Leha ho le jwalo, sehlopha sa tshepe e sa ruseng e sebediswang se lokela ho kgethwa ka hloko ho latela ditlhoko tse ikgethang tsa mocheso wa tshebediso.

7. Na diphaephe tsa tšepe e sa ruseng di loketse indasteri ya dijo le dino?

Karabo: E, diphaephe tsa tšepe e sa ruseng di sebediswa haholo indastering ya dijo le dino ka lebaka la bohloeki ba tsona, ho hanyetsa mafome le tlhokomelo e bonolo.

8. Phapang ke efe pakeng tsa di-socket welding fittings le di-butt welding fittings?

Karabo: Di-fitting tsa phaephe tse welded ka soketeng di kenya phaephe ka hara sokete ebe di etsa welding ya fillet ho hokela phaephe. Di-fitting tsa weld tsa butt, ka lehlakoreng le leng, di hloka hore dipheletso tsa phaephe di beveled ebe di welded.

9. Na disebediswa tsa diphaephe tsa tshepe e sa ruseng di ka sebediswa hape?

K: E, diphaephe tsa tšepe e sa ruseng di ka sebediswa hape haholo. Tshepe e sa ruseng ke thepa e tsitsitseng e ka sebediswang hape le ho sebediswa hape ntle le ho lahlehelwa ke thepa kapa boleng ba yona.

10. Melemo ea ho sebelisa liphaephe tsa tšepe e sa ruseng ke efe ha e bapisoa le lisebelisoa tse ling?

K: Lisebelisoa tsa liphaephe tsa tšepe e sa ruseng li fana ka melemo e mengata, joalo ka ho hanyetsa mafome hantle, matla a phahameng, ho tšoarella le thepa ea bohloeki. Ha li hloke tlhokomelo e ngata, li phela nako e telele 'me li na le ponahalo e hloekileng le e ntle.

TLHAHISO EA LIHLAHISOA TLHAHISO

1. Sefahleho

E ka phahamisoa sefahleho (RF), sefahleho se felletseng (FF), Lenonyello la Ring (RTJ), Groove, Leleme, kapa e etselitsoe uena.

2.Bevel e qetellang ho ya ka ANSI B16.25

3.CNC e felile hantle.

Qetello ea sefahleho: Qetello e ka lehlakoreng la flange e lekanngoa e le Bophahamo ba Average Roughness ba Arithmetical (AARH). Qetello e khethoa ke maemo a sebelisoang. Mohlala, ANSI B16.5 e bolela liqetello tsa sefahleho ka har'a sebaka sa 125AARH-500AARH (3.2Ra ho isa ho 12.5Ra). Liqetello tse ling li fumaneha ka kopo, mohlala 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra kapa 6.3/12.5Ra. Sebaka sa 3.2/6.3Ra se atile haholo.

HO TSHWAYA LE HO PHAKA

• Lera ka leng le sebelisa filimi ea polasetiki ho sireletsa bokaholimo

• Bakeng sa tšepe e sa ruseng kaofela e pakoa ka lebokose la plywood. Bakeng sa flange ea carbon e kholo e pakoa ka pallet ea plywood. Kapa e ka etsoa ka mokhoa o ikhethileng.

• Letšoao la ho romella le ka etsoa ha ho kopuoa

• Matshwao a dihlahiswa a ka betlwa kapa a printwa. OEM e a amoheleha.

TLHAHLOBO

• Teko ea UT

• Teko ea PT

• Teko ea MT

• Teko ea boholo

Pele ho pepa, sehlopha sa rona sa QC se tla hlophisa tlhahlobo ea NDT le tlhahlobo ea boholo. Hape se amohela TPI (tlhahlobo ea motho oa boraro).

Mokhoa oa Tlhahiso

| 1. Khetha thepa e tala ea 'nete | 2. Seha thepa e tala | 3. Ho futhumatsa pele ho nako |

| 4. Ho betla | 5. Kalafo ea mocheso | 6. Mechini e Mebe |

| 7. Ho cheka | 8. Ho lokisa ka hloko | 9. Ho tšoaea |

| 10. Tlhahlobo | 11. Ho paka | 12. Phano |

Nyeoe ea Tšebelisano-'moho

Projeke e Turkey, di-flange di sebediswa diphaepheng tsa kgase ya tlhaho. Di-flange tseo kaofela di amohetswe ke TUV.

LEQEPHE LA DITATA LA FLANGE

1. Litekanyo tsa Flange le mamello li tla ba ho latela ASME B16.5.

2. Li-flange li lokela ho hlahisoa ka ho betla.

3. Thepa e tla ba ho latela maemo a ASTM A105, ASTM A694 F65 le ASTM A694 F70.

4. Li-flange tsa ASTM A694 F65 le ASTM A694 F70 li lokela ho tingoa le ho halefisoa.

5. Lisetifikeiti tsa teko ea thepa le litlaleho tsa kalafo ea mocheso li tla fumaneha bakeng sa tlhahlobo ea TPI.

6. Li-flange tsa WN li lokela ho ba le lipheletso tsa bevel tse lumellanang le ASME B16.25.

7. Litekanyetso tsa liteko tsa lik'hemik'hale le tsa mechine (tšusumetso, chai, ho tenyetseha jj.) li tla latela maemo a amanang.

8. Libaka tsohle li lokela ho khabisoa ka mochini le ho penta ka varnish ka oli e bonaletsang ho thibela ho rusa.

9. Ho tshwaya ho tla kenyeletsa tlhahisoleseding e latelang,

• Bophara (nako e fedileng 6”)

• Sehlopha sa kgatello (nako e fedileng ke 150 LB)

• Sehlopha sa thepa (nako e fedileng ke ASTM A 105)

• Botenya ba lebota (nako e fedileng ke 4,78 mm)

• Nomoro ea Mocheso (e felloa ke nako 138413)

• Maemo a tlhahiso (ASME B16.5)

10. Thepa e lokela ho se be le diphoso le mapetso a bokaholimo. Litokiso tsa ho tjheseletsa di thibetswe ka thata.

11. Li-flange tsohle li lokela ho phahamisoa sefahlehong (RF) ka bokaholimo ba ho koala. Bokaholimo ba ho koala e lokela ho ba Ra 3,2 - 6,3 µm (125 - 250 mic. inc.) ho ea ho ASME B46.1.

12. Thepa e lokela ho pakoa ho thibela tshenyo hodima machining le ho kwala bokahodimo.

13. Litekanyo tsohle li tla ba ka mamello e ntle (+). Tolerances e fokolang e thibetsoe ka thata.

14. Li-bevelling tsa Flange li lokela ho etsoa hore li lumellane le ASME B16.25.

15. Tshebetso ea tlhahiso e tla hlahlojoa neng kapa neng ke TPI.

16. TPI e ka nka disampole ho tsoa thepa efe kapa efe bakeng sa sampole ea teko ea lik'hemik'hale/mechanical.

17. Tlaleho ea tlhahlobo e tlang e tla hlahlojoa ke TPI.

| Ntho | Boholo (Inchi) | Sehlopha sa Khatello | CS | Thepa | Boima ba 'mele (mm) | Sebaka | Bongata. |

| SORF | 12 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 32 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 14 | LIFANGE TSA TANK | 2 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 5.54 | LIFANGE TSA TANK | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 6 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 5.54 | LIFANGE TSA TANK | 8 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 14 | LIFANGE TSA TANK | 8 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 16 | LIFANGE TSA TANK | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | LIFANGE TSA TANK | 6 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 5.54 | LIFANGE TSA TANK | 8 |

| Flange, Molala oa Weld | 24 | 150LB | 20 | A105 | 14 | LIFANGE TSA TANK | 16 |

| Ntho | Boholo (Inchi) | Sehlopha sa Khatello | CS | Thepa | Boima ba 'mele (mm) | Sebaka | Bongata. |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Molala oa Weld | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Molala oa Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Molala oa Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Molala oa Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Molala oa Weld | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Molala oa Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Molala oa Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Molala oa Weld | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Molala oa Weld | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Molala oa Weld | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Molala oa Weld | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Molala oa Weld | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Molala oa Weld | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-PPR tris li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le li-elbow tsa tšepe ea alloy li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Liphaephe tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koentsha Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.

-

Lisebelisoa tsa Pipe A105 Class 150 Ss Carbon Steel Pl ...

-

Sekhahla se Tloaelehileng sa Khatello ea Orifice Flange se Thehiloeng ...

-

carbon tšepe weld molaleng mofuta 6″ ANSI SEHLOPHA ...

-

carbon tšepe a105 forge blind flange

-

ASTM A182 F51 F53 BL ANSI B16.5 Tšepe e sa ruseng ...

-

Flange ea orifice WN 4″ 900# RF A105 habeli gr ...