Flange ea orifice WN 4″ 900# RF A105

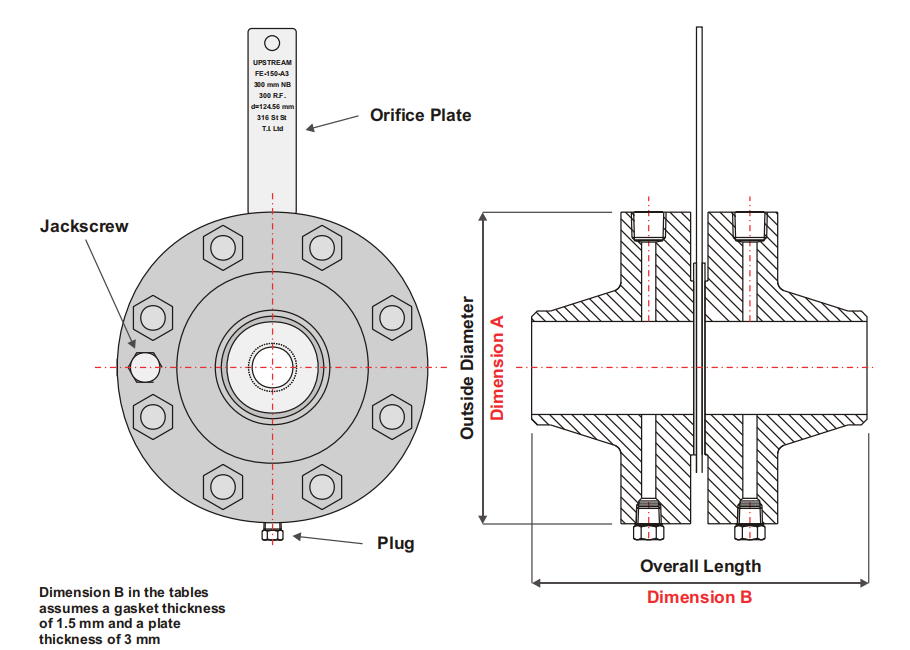

Flange ea 4" 900# Weld Neck Orifice Flange ho ASTM A105 e emela karolo ea tekanyo ea phallo e entsoeng ka nepo e etselitsoeng tšebeletso ea bohlokoa ea khatello e phahameng indastering ea oli le khase, petrochemical le tlhahiso ea motlakase. E entsoe ka ho latela ka tieo litekanyetso tsa ASME B16.36 (Orifice Flanges) le B16.5, flange ena e kenyelletsa masoba a mabeli a drain (vent) a Grade 3 joalo ka maemo a tloaelehileng, e nolofalletsa ho tobetsa ka nepo khatello le ho netefatsa tekanyo e tšepahalang ea khatello bakeng sa phetisetso ea tlhokomelo le taolo ea ts'ebetso.

TLHAHISO

| Lebitso la Sehlahisoa | tjheseletsa molaleng oa Orifice flange | |||

| SAESE | 1" holimo ho 24" | |||

| Khatello | 150#-2500# | |||

| E tloaelehileng | ANSI B16.36 | |||

| Botenya ba lebota | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS joalo-joalo. | |||

| Thepa | Tšepe e sa ruseng: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H,A182F316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo le jj. Tšepe ea k'habone: A105, A350LF2, Q235, St37, St45.8, A42CP, E24, A515 Gr60, A515 Gr 70 | |||

| Tšepe e sa ruseng habeli: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 le jj. Tšepe ea phaephe: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 jj. | ||||

| Motsoako oa nikeli: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 jj. Motsoako oa Cr-Mo: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3 jj. | ||||

| Kopo | Indasteri ea peterole; indasteri ea polokelo le ea lifofane; indasteri ea meriana; mosi oa khase; feme ea motlakase; moaho oa likepe; kalafo ea metsi, jj. | |||

| Melemo | setoko se loketse, nako ea ho fana ka potlako; e fumaneha ka boholo bohle, e etselitsoe; boleng bo holimo | |||

E entsoe ka tšepe ea carbon ea ASTM A105—e nang le netefatso e habeli bakeng sa ho latelwa ha eona ho ntlafalitsoeng—flange ena ea molala oa weld e fana ka matla a holimo a mechini le khanyetso ea tšusumetso. Tekanyo ea khatello ea 900# e netefatsa botšepehi lits'ebetsong tse sebetsang ho fihlela ho 1500 psi ho 100°F (ka ho fokotseha ha mocheso ho loketseng). Moralo oa eona o etelletsa pele phetoho e boreleli ho tloha phaepheng ho ea ho flange ka molala o kopaneng, e fokotsa pherekano le ho ntlafatsa maemo a phallo ho ea holimo le tlase ho poleiti ea orifice.

MAEMO A DIMENSION

TLHAHISO EA LIHLAHISOA TLHAHISO

Kaho e entsoeng ka maiketsetso:

Flange ka 'ngoe e qala e le billet ea tšepe ea khabone e futhumetseng, e entsoeng tlas'a khatello e phahameng ho ntlafatsa sebopeho sa lijo-thollo, ho ntlafatsa thepa ea mechini (haholo-holo ho tiea le ho hanyetsa mokhathala), le ho felisa likheo kapa likoli tse ka hare. Ts'ebetso ena e netefatsa ho tšoana le matla a phahametseng mekhoa e meng ea lahla kapa ea poleiti.

Ho Sebetsa ka ho Sebetsa:

Ho sebetsa ka mechine ea CNC ho tiisa mamello e matla libakeng tsohle tsa bohlokoa. Boro e entsoe ka mochini ho fihlela qetellong e boreleli ho fokotsa tšitiso ea phallo. Sefahleho se phahamisitsoeng se na le sekoti se nepahetseng (qetello ea 125-250 AARH) ho eketsa katleho ea ho tšoara ka gasket le ho tiisa. Masoba a bolt aa phunngoa 'me a shebane le matheba ho netefatsa hore ho bapaloa hantle le ho lekana ha bolt.

Likarolo tse Ikhethang tsa Orifice:

Flange e kenyelletsa masoba a mabeli a 1/2" NPT (kapa a lekanang) a Kereiti ya 3 a drain/vent a behilweng ka thoko ho di-degree tse 90, a latela dibopeho tse tloaelehileng tsa flange ya orifice bakeng sa dikgokelo tsa kgatello ya transmitter. Bokaholimo ba ho kopana bo etseditswe ho boloka poleiti e tloaelehileng ya orifice e nang le mokoti o tebileng, o bohale bakeng sa tekanyo e nepahetseng ya phallo.

Tokisetso ea ho tjheseletsa:

Qetello ea molala oa weld e betloa ka sekhutlo se tloaelehileng sa 37.5° ka mobu oa 1.6mm, o lokiselitsoe weld ea butt e kenellang ka botlalo ho ea ho phaephe e tsamaellanang ea Schedule 160. Moralo ona o netefatsa hore weld e tlosoa sefahlehong sa flange se nang le khatello e phahameng, e leng se fanang ka botšepehi bo phahameng ka ho fetisisa ba manonyeletso.

Setifikeiti sa Thepa:

E fanoe ka setifikeiti se felletseng sa ASTM A105 habeli (thepa ea lik'hemik'hale le ea mechini ho tsoa tlhahlobong ea mocheso le sehlahisoa), ho netefatsa hore thepa e fihlela kapa e feta litlhoko tsa matla a fokolang a tlhahiso (250 MPa) le matla a ho thaepa (485 MPa).

HO TSHWAYA LE HO PHAKA

Flange e 'ngoe le e 'ngoe ea orifice e lokisetsoa ka bonngoe bakeng sa ho romelloa. Kamora ho roala oli ea ho qetela e thibelang ho bola kapa VCI (Vapor Corrosion Inhibitor), flange e phutheloa ka polasetiki e boima kapa pampiri e sa keneleng metsi. Libaka tse bohlokoa tse entsoeng ka mochini - haholo-holo sefahleho se phahamisitsoeng le mokoti - li sirelelitsoe ka likhetla tsa polasetiki kapa tsa khateboto tse khaotsoeng ka mokhoa o ikhethileng. Li-flange li tlamelloa ka thata ho pallet ea lehong kapa li pakoa ka har'a kreiti ea lehong e matlafalitsoeng, ho latela bongata ba odara le sebaka seo li eang ho sona.

TLHAHLOBO

Setifikeiti sa Thepa: Flange ka 'ngoe e fanoa ka Setifikeiti se felletseng sa Teko ea Mill (MTC) se lumellanang le EN 10204 3.1 / ASTM A961. Setifikeiti sena se fana ka ho sala morao mocheso oa pele oa tšepe 'me se kenyelletsa:

Tlhahlobo e felletseng ea lik'hemik'hale (C, Mn, P, S, Si, Cu, jj.)

- Liphetho tsa liteko tsa mechini (Matla a ho Tenyetseha, Matla a ho Tena, Ho Lelefatsa, Phokotso ea Sebaka)

- Liphetho tsa liteko tsa Charpy Impact (haeba li totobalitsoe bakeng sa tšebeletso ea mocheso o tlase)

- Litlaleho tsa kalafo ea mocheso (ho etsa hore e be boemong bo tloaelehileng, haeba e sebelisoa)

Nyeoe ea Tšebelisano-'moho

E entsoe bakeng sa lits'ebetso tse nepahetseng tsa ho lekanya, flange ena e tiisa botsitso ba litekanyo tlas'a potoloho ea mocheso le khatello. Qetello ea Sefahleho se Phahameng (RF) e netefatsa tiiso e tšepahalang e nang le li-gasket tsa leqeba le potolohang kapa tse chitja, ha kaho ea lebota le boima la Schedule 160 e fana ka moeli o eketsehileng oa polokeho bakeng sa lits'ebeletso tsa ho theoha ha metsi kapa khatello e phahameng. Jwalo ka lejoe la motheo la tekanyo e sireletsehileng le e nepahetseng ea mokelikeli, flange ena ea orifice ke karolo ea bohlokoa bakeng sa baenjiniere ba batlang ho nepahala, ho tšoarella, le ho latela ka botlalo melao ea lisebelisoa tsa khatello ea machaba.

Mokhoa oa Tlhahiso

| 1Khetha thepa e tala ea 'nete | 2. Seha thepa e tala | 3. Ho futhumatsa pele ho nako |

| 4. Ho betla | 5. Kalafo ea mocheso | 6. Mechini e Mebe |

| 7. Ho cheka | 8. Ho lokisa ka hloko | 9. Ho tšoaea |

| 10. Tlhahlobo | 11. Ho paka | 12. Phano |

Maemo a Tšebeliso e Pharaletseng: Flange ena ea orifice ea 4" 900# e entsoe bakeng sa lits'ebetso tse hlokang boiteko liindastering tse 'maloa tsa bohlokoa:

- Oli le Khase: Liteishene tsa ho lekanya phetisetso ea tlhokomelo, li-manifold tsa tlhahiso ea li-wellhead, lithapo tsa ho hula/ho ntša li-compressor station, le lithapo tsa ts'ebetso ea ho hloekisa bakeng sa lihlahisoa tse tala, khase, kapa tse hloekisitsoeng.

- Petrokhemikhale le Lik'hemik'hale: Taolo e nepahetseng ea phepelo ho li-reactor, tekanyo ea phallo ea melapo e mabifi kapa ea boleng bo holimo ea ts'ebetso, le litsamaiso tsa mouoane le condensate tsa thuso.

- Tlhahiso ea Motlakase: Methapo e meholo ea mouoane, metsi a fepeloang, le khase ea mafura lifemeng tsa motlakase tse futhumatsang, moo tekanyo e nepahetseng ea phallo ea boima e leng ea bohlokoa bakeng sa katleho le polokeho.

- Lisebelisoa tse Matla: Feme efe kapa efe ea indasteri e hlokang tekanyo e tšepahalang le e tšepahalang ea phallo bakeng sa taolo ea ts'ebetso, boikarabello, kapa ho hokahana ka polokeho.

Melemo ea Phepelo ea Khamphani ea Rona:

- Ho Theha le ho Etsa Mechini ka Hare ho Ntlo: Re boloka taolo e felletseng hodima tshebetso ya tlhahiso—ho tloha ho thepa e tala ho isa ho flange e fedisitsweng—re netefatsa boleng, ho latelwa le ho kgomarela kemiso.

- Botsebi ba Theknoloji: Sehlopha sa rona sa boenjiniere se ka fana ka tšehetso mabapi le boholo ba orifice, khetho ea gasket, litlhaloso tsa torque ea ho kenya, le ho latela maemo a ikhethileng a projeke (mohlala, Shell DEPs, maemo a Aramco).

- Ho tenyetseha le ho Etsa Lintho ka Tsela e Ikgethang: Leha re fana ka di-flange tse tloaelehileng tsa B16.36, re ka boela ra amohela ditlhoko tse ikgethang, tse kang dibopeho tse fapaneng tsa masoba a ho pompo (dipompo tsa sekhutlo, dipompo tsa radius), dikoahelo tse ikgethang, kapa kalafo ya mocheso bakeng sa ditshebediso tsa mocheso o tlase.

- Tlholisano ea Thepa: Joaloka moetsi ea tobileng ea nang le boiphihlelo bo boholo ba ho romela thepa kantle ho naha, re fana ka linako tse tšepahalang tsa ho etella pele le ho ntlafatsa liphutheloana le thomello ho isa libakeng tsa mesebetsi lefatšeng ka bophara ka mokhoa o theko e tlaase.

- Netefatso ea Boleng: Boitlamo ba rona bo fetela ka nģ'ane ho phano. Re fana ka litokomane tse felletseng le tšehetso ho netefatsa hore li-flange tsa rona li kopana hantle le litsamaiso tsa hau tsa liphaephe, li fana ka lilemo tsa tšebeletso e tšepahalang le e nepahetseng.

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-PPR tris li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le li-elbow tsa tšepe ea alloy li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Liphaephe tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koentsha Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.

-

AMSE B16.5 A105 e entsoeng ka tšepe ea carbon weld molaleng f ...

-

ASME B 16.5 CS SA 105N LWNFF 20inch 600LB LWN F...

-

ASME b16.48 Fektheri ea thekiso ea tšepe ea carbon setšoantšo sa 8 ...

-

Custom High Quality 304 Stainless Steel Flanged Flanged ...

-

Ansi B16.5 A105 Black Carbon Steel Slip holim'a Flange

-

ANSI B16.5 Tšepe e sa Tšoarellang e entsoeng ka ho tjheseletsa F ...