SS 304 le 316 Sekoahelo sa Pipe ea Bohloeki ea Tšepe e sa Khaotseng

Li-Fittings tsa rona tsa SS 304 le 316 tsa Tšepe e sa Khaotseng li entsoe ho fihlela litlhoko tse thata ka ho fetisisa tsa bohloeki tsa lijo le lino, meriana, theknoloji ea baeloji le litlolo. Jwalo ka likarolo tsa bohlokoa lits'ebetsong tsa liphaephe tsa ts'ebetso ea bohloeki, li-elbow tsena tse entsoeng ka nepo, li-tee le li-fitting tse tlatsetsang li netefatsa bohloeki ba sehlahisoa, li thibela tšilafalo, 'me li nolofatsa mekhoa e sebetsang ea ho hloekisa.

Li entsoe ka AISI 304 e netefalitsoeng kapa tšepe e sa ruseng ea 316/316L e sa ruseng e nang le mafome e phahameng, li-fitting tsena li na le meralo e se nang mapetso e nang le libaka tse bentšitsoeng ka hare tse fetang maemo a indasteri bakeng sa ho hloeka. Li fumaneha ka likhetho tse ngata tsa khokahano ho kenyeletsoa le Tri-Clamp le orbital butt weld, li fana ka litharollo tse feto-fetohang bakeng sa ho kenya le litsamaiso tse sa feleng tse hlokang ho qhaqhoa khafetsa bakeng sa tlhokomelo kapa ho fetola li-batch. Fitting ka 'ngoe e entsoe ka maoto a sa shoeng ho thibela ho koalloa ha baktheria 'me e lumellana ka botlalo le mekhoa ea Clean-in-Place (CIP) le Sterilize-in-Place (SIP), ho netefatsa ho latela melao ea lefats'e ea bohloeki le litlhoko tsa GMP.

Leqephe la lintlha

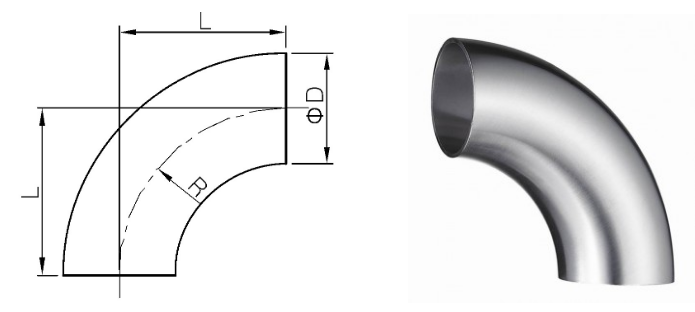

Tekanyo ea Setsoe sa ho Weld sa Bohloeki 90 degree -3A (yuniti:mm)

| SAESE | D | L | R |

| 1/2" | 12.7 | 19.1 | 19.1 |

| 3/4" | 19.1 | 28.5 | 28.5 |

| 1" | 25.4 | 38.1 | 38.1 |

| 1/1/4" | 31.8 | 47.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 57.2 |

| 2" | 50.8 | 76.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 95.3 |

| 3" | 76.2 | 114.3 | 114.3 |

| 4" | 101.6 | 152.4 | 152.4 |

| 6" | 152.4 | 228.6 | 228.6 |

Tekanyo ea Setsoe sa Bohloeki sa Weld 90 degree -DIN (Yuniti:mm)

| SAESE | D | L | R |

| DN10 | 12 | 26 | 26 |

| DN15 | 18 | 35 | 35 |

| DN20 | 22 | 40 | 40 |

| DN25 | 28 | 50 | 50 |

| DN32 | 34 | 55 | 55 |

| DN40 | 40 | 60 | 60 |

| DN50 | 52 | 70 | 70 |

| DN65 | 70 | 80 | 80 |

| DN80 | 85 | 90 | 90 |

| DN100 | 104 | 100 | 100 |

| DN125 | 129 | 187 | 187 |

| DN150 | 154 | 225 | 225 |

| DN200 | 204 | 300 | 300 |

Tekanyo ea Setsoe sa Bohloeki sa Weld 90 degree -ISO/IDF (Yuniti:mm)

| SAESE | D | L | R |

| 12.7 | 12.7 | 19.1 | 19.1 |

| 19 | 19.1 | 28.5 | 28.5 |

| 25 | 25.4 | 33.5 | 33.5 |

| 32 | 31.8 | 38 | 38 |

| 38 | 38.1 | 48.5 | 48.5 |

| 45 | 45 | 57.5 | 57.5 |

| 51 | 50.8 | 60.5 | 60.5 |

| 57 | 57 | 68 | 68 |

| 63 | 63.5 | 83.5 | 83.5 |

| 76 | 76.2 | 88.5 | 88.5 |

| 89 | 89 | 103.5 | 103.5 |

| 102 | 101.6 | 127 | 127 |

| 108 | 108 | 152 | 152 |

| 114.3 | 114.3 | 152 | 152 |

| 133 | 133 | 190 | 190 |

| 159 | 159 | 228.5 | 228.6 |

| 204 | 204 | 300 | 300 |

| 219 | 219 | 305 | 302 |

| 254 | 254 | 372 | 375 |

| 304 | 304 | 450 | 450 |

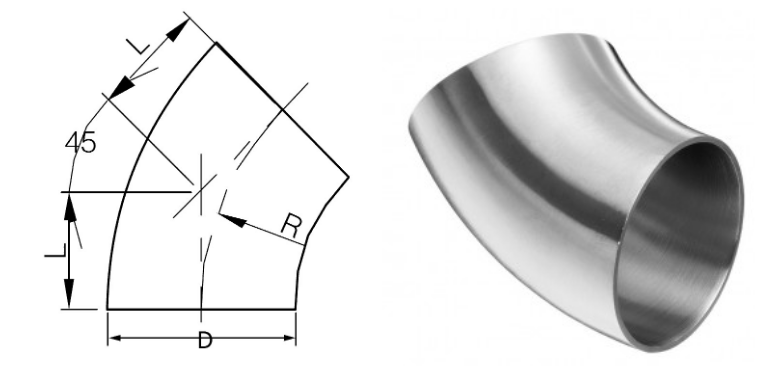

Tekanyo ea Setsoe sa ho Weld sa Bohloeki - likhato tse 45 -3A (yuniti:mm)

| SAESE | D | L | R |

| 1/2" | 12.7 | 7.9 | 19.1 |

| 3/4" | 19.1 | 11.8 | 28.5 |

| 1" | 25.4 | 15.8 | 38.1 |

| 1 1/4" | 31.8 | 69.7 | 47.7 |

| 1 1/2" | 38.1 | 74.1 | 57.2 |

| 2" | 50.8 | 103.2 | 76.2 |

| 2 1/2" | 63.5 | 131.8 | 95.3 |

| 3" | 76.2 | 160.3 | 114.3 |

| 4" | 101.6 | 211.1 | 152.4 |

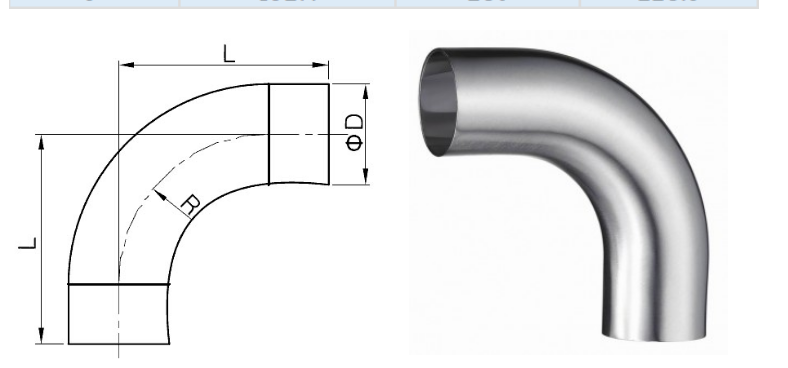

Tekanyo ea Setsoe sa ho Weld sa Bohloeki - 90 degree -3A (yuniti:mm)

| SAESE | D | L | R |

| 1/2" | 12.7 | 19.1 | 19.1 |

| 3/4" | 19.1 | 28.5 | 28.5 |

| 1" | 25.4 | 38.1 | 38.1 |

| 1 1/4" | 31.8 | 47.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 57.2 |

| 2" | 50.8 | 76.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 95.3 |

| 3" | 76.2 | 114.3 | 114.3 |

| 4" | 101.6 | 152.4 | 152.4 |

| 6" | 152.4 | 228.6 | 228.6 |

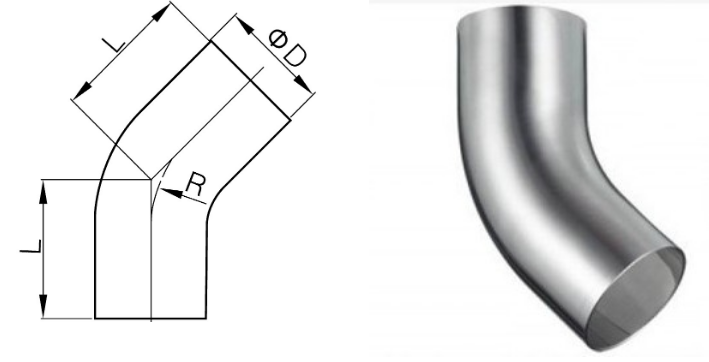

Tekanyo ea Setsoe sa ho Weld sa Bohloeki - likhato tse 45 tse nang le Lipheletso tse Otlolohileng -SMS (Yuniti:mm)

| SAESE | D | L | R |

| 25 | 25.4 | 45 | 25 |

| 32 | 31.8 | 53.3 | 32 |

| 38 | 38.1 | 56.7 | 38 |

| 51 | 50.8 | 63.6 | 51 |

| 63 | 63.5 | 80.8 | 63.5 |

| 76 | 76.2 | 82 | 76 |

| 102 | 101.6 | 108.9 | 150 |

HO HLAHLOBA

Litlhaloso tsa Thepa:

AISI 304 (CF8): 18-20% Chromium, 8-10.5% Nickel – Khanyetso e ntle ea ts'enyeho e akaretsang

AISI 316/316L (CF3M): 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum – Khanyetso e phahameng ea chloride

Setifikeiti sa Thepa: Thepa eohle e fanoa ka setifikeiti sa EN 10204 3.1 le ho fumaneha ka botlalo

Mefuta e Tlase ea Khabone: 316L (<0.03% C) e fumaneha bakeng sa lits'ebetso tse hlokang ho tjheseletsa ho ntlafalitsoeng

Likarolo tsa Moralo oa Bohloeki:

Moralo oa Leoto le Shoeleng la Zero: Mahlaseli a ka hare ≤1.5D ka litlhoko tsa ASME BPE

Kaho e se nang mapetso: Libaka tse bentšitsoeng tse tsoelang pele tse nang le mahlaseli a bonyane a 3mm

Geometry e ka Ntšang Metsi: Likhutlo tse itlhoekisang li thibela ho koaleha ha metsi

Liphetoho tse Boreleli: Liphetoho tse tsamaeang butle-butle ho fokotsa moferefere

E ka hloekisoa: E netefalitsoe bakeng sa potoloho ea ho hloekisa mouoane e pheta-phetoang

Bokhabane ba Tlhahiso:

Ho theha ka nepo: Ho theha serame kapa ho etsa hydroforming bakeng sa botenya ba lebota bo tsitsitseng

Ho Welding ea Orbital: Bakeng sa li-fittings tsa ho weld ea butt, ho netefatsa ho kenella ka botlalo ka mocheso o fokolang

Ho Phahamisa ka ho Tsoela Pele: Ho Phahamisa ka mechine ka mekhahlelo e mengata (tatelano ea grit e fetang 180-600)

Ho polisha ka motlakase: Mokhoa oa boikhethelo oa lik'hemik'hale tsa motlakase bakeng sa ho hanyetsa ho ts'enyeha ho matla

Passivation: Kalafo ea asiti ea nitrike ho latela ASTM A967 ho tsosolosa lera la chromium oxide

Sistimi ea Khokahano:

Setlamo se Tharo: Setlamo se tloaelehileng sa 1.5" se nang le li-ferrule tse bentšitsoeng tsa 304/316

Ho Weld ea Butt: Lipheletso tse lokisitsoeng bakeng sa ho weld ea orbital (ho hokahanya ID/OD ka har'a 0.1mm)

Setulo sa Bevel: Likhokahano tsa setaele sa ISO tse nang le polokelo ea gasket ea bohloeki

Ho Khaotsa ka Potlako: Likhokahano tsa Aseptic bakeng sa kopano/ho qhaqha khafetsa

Ho Tšoaea le ho Latela Boleng:

Ho Tšoaea ka Laser: Ho tšoaea ka ho sa feleng ka sehlopha sa thepa, boholo le palo ea lotho

Ho Khouta Mebala: Meqhaka ea mebala e khethiloeng bakeng sa ho khetholla habonolo litsamaisong tse tsoakiloeng

Ho tšoaea RFID: E fumaneha bakeng sa litsamaiso tsa thepa le tsa ho latela tse iketsahalletseng

Kopo

Mekhoa ea Metsi:

Li-loop tsa kabo ea WFI (Metsi bakeng sa Ente) le PW (Metsi a Hloekisitsoeng)

Li-bioreactor:

Ho lokisa mecha ea phatlalatso, kotulo le mela ea mehlala

Mekhoa ea ho Hloekisa:

Mekhoa ea ho sefa ea chromatography le litsamaiso tsa ho sefa ka bongata

Tlhahiso:

Tokisetso ea li-buffer le mela ea phetisetso ea sehlahisoa

Mouoane o Hloekileng:

Mekhoa ea ho bokella le ho aba kontinente

P: Na o ka amohela TPI?

K: E, ehlile. Rea u amohela etela fektheri ea rona 'me u tle mona ho tla hlahloba thepa le ho hlahloba ts'ebetso ea tlhahiso.

P: Na o ka fana ka Foromo e, Setifikeiti sa tšimoloho?

A: E, re ka fana ka.

P: Na o ka fana ka invoice le CO ho chamber of commerce?

A: E, re ka fana ka.

P: Na o ka amohela L/C e diehisitsweng matsatsi a 30, 60, kapa 90?

K: Re ka khona. Ka kopo buisana le thekiso.

P: Na o ka amohela tefo ya O/A?

K: Re ka khona. Ka kopo buisana le thekiso.

P: Na o ka fana ka disampole?

K: E, disampole tse ding ke mahala, ka kopo sheba le thekiso.

P: Na o ka fana ka dihlahiswa tse dumellanang le NACE?

K: E, re ka khona.

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-PPR tris li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le li-elbow tsa tšepe ea alloy li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Liphaephe tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koentsha Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.

-

sesupa-tsela se se nang letho sa paddle A515 gr 60 figure 8 spectac...

-

fektheri DN25 25A sch160 90 degree litsoeng pipe fi ...

-

304 316 Bohloeki ba Pneumatic bo sa senyeheng B bo sebetsang ...

-

1″ 33.4mm DN25 25A sch10 litsoeng pipe fitti ...

-

Pipe ea Tšepe e sa Khaotseng ea ASTM e tloaelehileng ea 304/316/316L ...

-

carbon tšepe weld molaleng mofuta 6″ ANSI SEHLOPHA ...