LIPARAMETERI TSA SEHLAHISOA

| Lebitso la Sehlahisoa | Qetello ea sekoti |

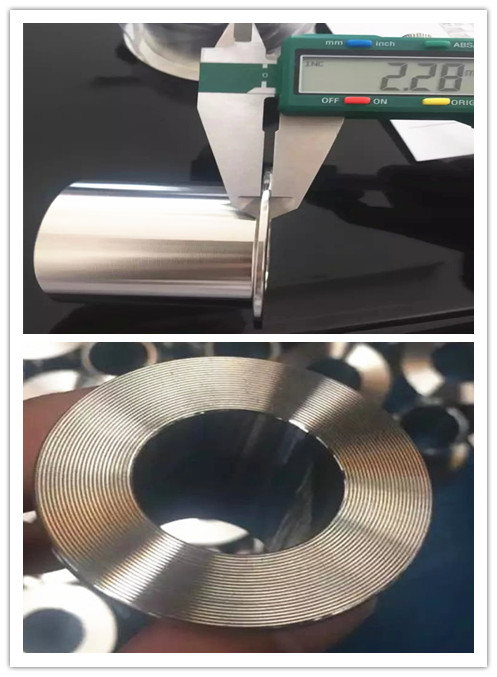

| Boholo | Sekoahelo sa 1/2"-24" se se nang sekoahelo, se kopantsoe ka 26"-60" |

| E tloaelehileng | ANSI B16.9, MSS SP 43, EN1092-1, e etselitsoeng motho ka mong, le jj. |

| Botenya ba lebota | SCH5S, SCH10, SCH10S, STD,XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS, e etselitsoeng 'mele le jj. |

| Mofuta | E telele le e kgutshwane |

| QETA | Bevel end/BE/buttweld |

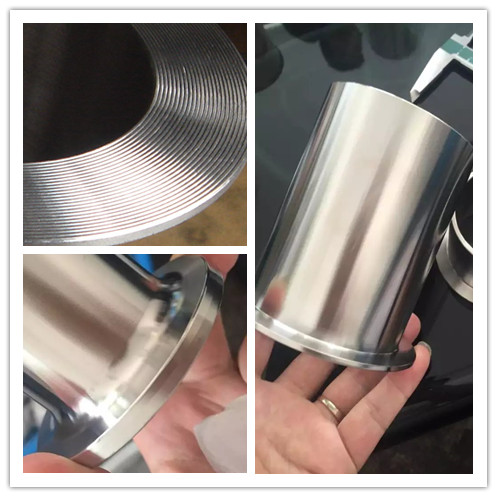

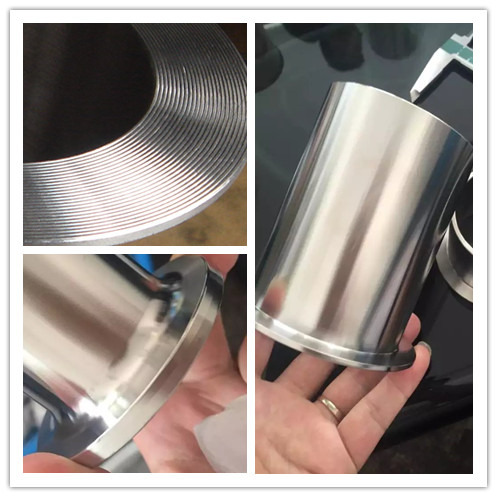

| Bokaholimo | e halikiloeng, lehlabathe le phutholohileng |

| Thepa | Ts'epe e sa beng le mabali:A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo le jj. |

| Tšepe e sa ruseng habeli:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 le tse ding. | |

| motsoako oa nikeli:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 jj. | |

| Kopo | Indasteri ea peterole; indasteri ea lifofane le lifofane; indasteri ea meriana, mosi oa khase; setsi sa motlakase; mohaho oa likepe; kalafo ea metsi, jj. |

| Melemo | setoko se loketse, nako ea ho fana ka potlako; e fumaneha ka boholo bohle, e etselitsoe; boleng bo holimo |

SETLHOPHO SE SEKHUTŠOANE/SE TELELE SE KHUTŠOAANE (ASA/MSS)

Lipheletso tsa lithupa li fumaneha ka mekhoa e 'meli e fapaneng:

- paterone e kgutshwane, e bitswang dipheletso tsa stub tsa MSS-A

- paterone e telele, e bitsoang ASA-A stub ends (kapa ANSI length stub end)

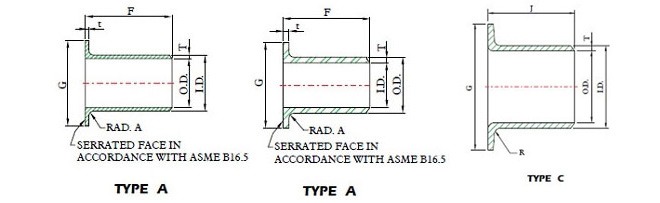

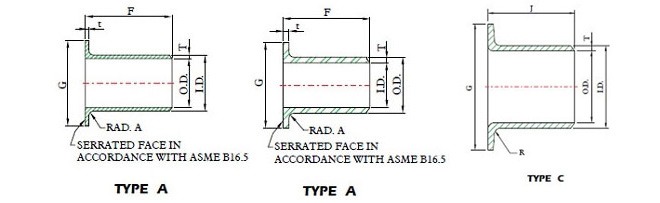

Mefuta ea Qetello ea Sekoti

Lipheletso tsa lithupa li fumaneha ka mefuta e meraro e fapaneng, e bitsoang "Mofuta oa A", "Mofuta oa B" le "Mofuta oa C":

- Mofuta oa pele (A) o etsoa le ho etsoa ka mechini ho latela flange e tloaelehileng ea ho tšehetsa mahlakore a kobehileng (lihlahisoa tsena tse peli li lokela ho sebelisoa hammoho). Libaka tse hokahaneng li na le boemo bo tšoanang ho lumella ho jara sefahleho se phatsimang ka bonolo.

- Lipheletso tsa lithupa tsa mofuta oa B li lokela ho sebelisoa le li-flange tse tloaelehileng tsa ho thellisa

- Lipheletso tsa stub tsa mofuta oa C li ka sebelisoa ka li-lap joint kapa li-slip-on flanges 'me li entsoe ka liphaephe.

MELEMO EA LIPHELELO TSA LIP FOROMO TSA LAP FOROMO

Ho tla hlokomeloa hore lipheletso tsa stud li ntse li tuma le lits'ebetsong tse nang le khatello e phahameng (haeba li ne li sebelisoa bakeng sa lits'ebetso tse nang le khatello e tlase feela nakong e fetileng).

LITŠOANTŠO TSE HLAKILENG

1. Bofelo ba bevel ho ya ka ANSI B16.25.

2. Ntle le lamination le mapetso

3. Ntle le litokiso tsa ho tjheseletsa

4. Kalafo ea bokaholimo e ka etsoa ka ho khena kapa ka ho sebelisa mochini o benyang oa CNC. Ka 'nete, theko e fapane. Bakeng sa litšupiso tsa hau, bokaholimo bo khena bo theko e tlase.

HO TŠOAEA

Mosebetsi o fapaneng oa ho tšoaea o ka etsoa ha o kopa. Re amohela letšoao la hau la LOGO.

TLHAHLOBO

1. Litekanyo tsa litekanyo, tsohle li le ka har'a mamello e tloaelehileng.

2. Mamello ea botenya: +/- 12.5%, kapa ka kopo ea hau

3. PMI

4. Teko ea PT, UT, X-ray

5. Amohela tlhahlobo ea motho oa boraro

6. Phepelo ea MTC, setifikeiti sa EN10204 3.1/3.2, NACE

HO PHAKISA LE HO ROMELA

1. E pakiloe ka lebokose la plywood kapa pallet ea plywood ho latela

2. re tla beha lethathamo la ho paka sephutheloana se seng le se seng

3. Re tla beha matšoao a ho romela thepa sephutheloana se seng le se seng. Mantsoe a matšoao a tla etsoa ka kopo ea hau.

4. Lisebelisoa tsohle tsa patsi ha li na mouoane

Lipheletso tsa lithupa li fumaneha ka mekhoa e 'meli e fapaneng:

- paterone e kgutshwane, e bitswang dipheletso tsa stub tsa MSS-A

- paterone e telele, e bitsoang ASA-A stub ends (kapa ANSI length stub end)

Lipheletso tsa lithupa li fumaneha ka mefuta e meraro e fapaneng, e bitsoang "Mofuta oa A", "Mofuta oa B" le "Mofuta oa C":

- Mofuta oa pele (A) o etsoa le ho etsoa ka mechini ho latela flange e tloaelehileng ea ho tšehetsa mahlakore a kobehileng (lihlahisoa tsena tse peli li lokela ho sebelisoa hammoho). Libaka tse hokahaneng li na le boemo bo tšoanang ho lumella ho jara sefahleho se phatsimang ka bonolo.

- Lipheletso tsa lithupa tsa mofuta oa B li lokela ho sebelisoa le li-flange tse tloaelehileng tsa ho thellisa

- Lipheletso tsa stub tsa mofuta oa C li ka sebelisoa ka li-lap joint kapa li-slip-on flanges 'me li entsoe ka liphaephe.

1. E fokotsa litšenyehelo ka kakaretso tsa lenonyello le flanged

Ka kakaretso, flange ea lesoba e nang le lesoba e na le boleng bo tlase ho feta thepa ea pheletso ea stub le mosebetsi oa liphaephe, kahoo ho boloka boima bohle ba thepa ea boleng bo holimo e sebelisoang bakeng sa lesoba le nang le lesoba.

Mohlala:

Bakeng sa phaephe ea SS316, ho e-na le ho sebelisa flange e felletseng ea ho welding ea 316, motsoako oa ntlha ea stub ea SS316 le flange ea lap joint ea tšepe ea carbon li tla etsa mosebetsi o tšoanang hantle, empa boima bohle ba thepa ea SS316 bo tla ba tlase, le litšenyehelo hape.

Ha e le hantle, dintlha tsa stub di dumella ho fokotsa boima ba thepa ya boleng bo hodimo ka hara diphaephe tse sa hlwekang, tse nang le duplex, le tse nang le nickel alloy, e leng se bolokang ditjeo. Ehlile, ha bophara le sehlopha sa di-flange di le kgolo, poloko e ba hodimo!

2. E nolofalletsa ho kenngoa ha flange

Flange ea letheka e ka potoloha phaepheng 'me ea nolofatsa ho hokahanya ha masoba a li-bolt a li-flange tse kopanang.

Ho tla hlokomeloa hore lipheletso tsa stud li ntse li tuma le lits'ebetsong tse nang le khatello e phahameng (haeba li ne li sebelisoa bakeng sa lits'ebetso tse nang le khatello e tlase feela nakong e fetileng).

Linepe tse qaqileng

1. Bofelo ba bevel ho ya ka ANSI B16.25.

2. Ntle le lamination le mapetso

3. Ntle le litokiso tsa ho tjheseletsa

4. Kalafo ea bokaholimo e ka etsoa ka ho khena kapa ka ho sebelisa mochini o benyang oa CNC. Ka 'nete, theko e fapane. Bakeng sa litšupiso tsa hau, bokaholimo bo khena bo theko e tlase.

Lipheletso tsa lithupa li ka odarwa ka lipheletso tse fapaneng tsa ho qetela:

- Lipheletso tse Beveled

- Lipheletso tse Sekwere

- Lipheletso tse Fetotsoeng

- Lipheletso tse Koetsoeng

- Lipheletso tse Khoele (Tse Nyenyane Feela)

1. Tšepe ea Khabone: A234 WPB Kereiti ea B

2. Tšepe e sa ruseng: 304/304L, 304H, 316/316L, 316H, 317L, 904L, 309S/H, 310S, 321, 6XN, 20CB, 347,254SMO

3.Duplex /Super Duplex:2205,Zeron 100,2507,410

4. Li-Alloys tsa Nickel: HC22, HB-3, HG3, HX, HC2000, HC276, NCI, NC, N, NL, NCMC, NICMC, NIC10, NIC11

Ho tšoaea

Mosebetsi o fapaneng oa ho tšoaea o ka etsoa ha o kopa. Re amohela letšoao la hau la LOGO.

Tlhahlobo

1. Litekanyo tsa litekanyo, tsohle li le ka har'a mamello e tloaelehileng.

2. Mamello ea botenya: +/- 12.5%, kapa ka kopo ea hau

3. PMI

4. Teko ea PT, UT, X-ray

5. Amohela tlhahlobo ea motho oa boraro

6. Phepelo ea MTC, setifikeiti sa EN10204 3.1/3.2, NACE

Ho paka le ho Romela

1. E pakiloe ka lebokose la plywood kapa pallet ea plywood ho latela

2. re tla beha lethathamo la ho paka sephutheloana se seng le se seng

3. Re tla beha matšoao a ho romela thepa sephutheloana se seng le se seng. Mantsoe a matšoao a tla etsoa ka kopo ea hau.

4. Lisebelisoa tsohle tsa patsi ha li na mouoane

Li-fitting tsa liphaephe ke likarolo tsa bohlokoa tsamaisong ea liphaephe, tse sebelisetsoang ho hokahanya, ho fetisetsa pele, ho khelosa, ho fetola boholo, ho koala kapa ho laola phallo ea metsi. Li sebelisoa haholo masimong a kang kaho, indasteri, matla le lits'ebeletso tsa masepala.

Mesebetsi ea Bohlokoa:E ka etsa mesebetsi e kang ho hokahanya liphaephe, ho fetola tsela eo phallo e tsamaeang ka eona, ho arola le ho kopanya phallo, ho lokisa bophara ba liphaephe, ho koala liphaephe, ho laola le ho laola.

Sebaka sa Kopo:

- Phepelo ea metsi le drainage ea moaho:Li-elbow tsa PVC le li-PPR tris li sebelisoa bakeng sa marang-rang a liphaephe tsa metsi.

- Liphaephe tsa indasteri:Li-flange tsa tšepe e sa ruseng le li-elbow tsa tšepe ea alloy li sebelisoa ho tsamaisa lik'hemik'hale.

- Tsamaiso ea matla:Liphaephe tsa tšepe tse nang le khatello e phahameng li sebelisoa liphaepheng tsa oli le khase.

- HVAC (Ho Futhumatsa, ho Fehla Moea, le ho Koentsha Moea):Li-fitting tsa liphaephe tsa koporo li sebelisoa ho hokahanya liphaephe tsa sehatsetsing, 'me manonyeletso a tenyetsehang a sebelisoa bakeng sa ho fokotsa ho thothomela.

- Nosetso ea temo:Lihokelo tse potlakileng li nolofatsa ho kopanngoa le ho qhaqhoa ha litsamaiso tsa ho nosetsa tsa sprinkler.

-

Serope se kopantsoeng sa tšepe e sa hloekang se nang le seamless 321ss ...

-

Tšepe e sa hloekang ea 304L Butt-Weld Pipe Fitting Se ...

-

k'habone tšepe mocheso o tlase tšepe koba litsoeng w ...

-

Lisebelisoa tsa liphaephe tsa SUS304 316 Tšepe e sa hloekang ...

-

Sekoahelo sa phala ea tšepe e sa hloekang ea lisenthimithara tse 8 ...

-

sch80 ss316 tšepe e sa hloekang e entsoeng ka ...